Mechanical stretch fabric is gaining popularity in the textile industry as a solution for garments that need stretch and comfort without spandex. As more clothing brands and fabric buyers look for sustainable, durable materials, it’s important to understand what mechanical stretch fabric is and what it can do.

Mechanical stretch fabric is fabric that gets its stretch from finishing processes instead of spandex or other elastic fibers. It has structural elasticity with an elongation rate of less than 9%. This means it’s comfortable, durable, and versatile for many applications.

In this article, we’ll look at what mechanical stretch fabric is, what it does, and what to think about when you’re buying fabric or making clothes.

What does mechanical stretch fabric mean?

Mechanical stretch fabric is fabric that gets its stretch from special finishing processes instead of spandex or other elastic fibers. This is usually done with high twist yarns and heat-setting processes that let the fabric stretch and recover without using elastic.

The high twist yarns in mechanical stretch fabrics are tightly twisted so they have a spring-like structure that lets the fabric stretch. During the finishing process, these yarns are heat-set, which locks in the stretch. This gives you fabric that can stretch and recover without losing its shape or stability.

Mechanical stretch fabrics are great when you need some stretch but don’t want to sacrifice the fabric’s stability or appearance. They have a more natural stretch than fabrics with spandex, which makes them good for casual wear, sportswear, and workwear.

What is the difference between mechanical stretch and spandex?

Mechanical stretch fabric and spandex fabric are both designed to give you stretch and comfort, but they do it in different ways and with different amounts of stretch.

Mechanical stretch fabric gets its stretch from high twist yarns and special finishing processes. It has structural elasticity with an elongation rate of less than 9%. This means it’s comfortable and durable without using elastic fibers. The stretch is usually more subtle and natural, so it’s good for garments that need some stretch.

Spandex fabric, on the other hand, has elastic fibers like spandex or elastane. These fibers give you a lot of stretch and recovery with an elongation rate of over 14%. This makes spandex fabric very stretchy and able to go back to its original shape after you stretch it. You’ll find spandex in things like activewear, swimwear, and undergarments where you need a lot of stretch and recovery.

Mechanical stretch fabrics are different from spandex fabrics in that they offer a more natural and subtle stretch. They also have the advantage of being more durable and resistant to wear and tear, making them suitable for a wider range of applications. Finally, mechanical stretch fabrics can be more environmentally friendly because they don’t require the use of synthetic elastic fibers.

What are the benefits of mechanical stretch fabric?

Mechanical stretch fabrics offer several benefits that make them a popular choice for various applications. These benefits include enhanced comfort, flexibility, and durability, making them ideal for a wide range of garments and textiles.

- Enhanced Comfort: Mechanical stretch fabrics provide a comfortable fit without the use of spandex or other elastic fibers. The natural stretch properties of these fabrics allow for greater freedom of movement, making them ideal for activewear, sportswear, and casual wear.

- Flexibility: Mechanical stretch fabrics get their flexibility from the use of high twist yarns and heat-setting techniques. This allows the fabric to stretch and recover without losing its shape or stability. The stretch is more natural compared to spandex-blended fabrics.

- Durability: Mechanical stretch fabrics are more durable and resistant to wear and tear than spandex fabrics. Because they don’t contain elastic fibers, these fabrics are less likely to degrade over time. This makes them a long-lasting option for a variety of applications.

- Environmental Benefits: Mechanical stretch fabrics can be more environmentally friendly than spandex-blended fabrics. The use of high twist yarns and heat-setting techniques eliminates the need for synthetic elastic fibers, which reduces the environmental impact of fabric production.

- Versatility: Mechanical stretch fabrics can be used in a wide range of applications, from casual wear and sportswear to workwear and home textiles. Their natural stretch properties make them suitable for garments that require moderate flexibility and comfort.

Do mechanical stretch fabrics perform the same as other fabrics?

Mechanical stretch fabrics perform the same as other fabrics in terms of color fastness, shrinkage, and other chemical properties. This means you can use them in the same applications as other fabrics without sacrificing quality or performance.

Color fastness is an important consideration for any fabric. It refers to the fabric’s ability to resist fading and color bleeding. Mechanical stretch fabrics have color fastness similar to other fabrics. This is important for garments that are exposed to frequent washing and wear because it ensures the fabric will maintain its appearance over time.

Shrinkage is another important factor to consider when choosing a fabric. Mechanical stretch fabrics are designed to minimize shrinkage so garments retain their shape and size after washing. This is achieved through the use of high twist yarns and heat-setting techniques that lock in the fabric’s stretch properties.

When you order mechanical stretch fabrics, it’s important to communicate your specific requirements to the factory. This includes details such as wash fastness, shrinkage rates, and other performance indicators. By specifying these requirements, you can ensure the fabric meets your desired standards and performs consistently in your applications.

What types of garments use mechanical stretch fabric?

Mechanical stretch fabrics are used in a wide range of garments and textiles. They provide flexibility and comfort without sacrificing durability or appearance. Some common applications include:

- Sportswear: Activewear, yoga pants, running shorts, and other sportswear benefit from the natural stretch properties of mechanical stretch fabrics. They allow for greater freedom of movement.

- Casual Wear: Mechanical stretch fabrics are used in jeans, t-shirts, and casual pants. They provide a more natural stretch that enhances comfort and durability.

- Workwear: Mechanical stretch fabrics are used in uniforms, overalls, and other work garments. They provide a comfortable fit and resistance to wear and tear.

- Home Textiles: Mechanical stretch fabrics are used in bed linens, curtains, upholstery, and other home textiles. They provide flexibility and comfort.

Are there any fabrics that cannot be made into mechanical stretch?

While mechanical stretch is a versatile and practical solution, not all fabrics can achieve this property effectively due to process limitations. Some fabrics may not respond well to the finishing processes used to create mechanical stretch, resulting in less effective stretch properties.

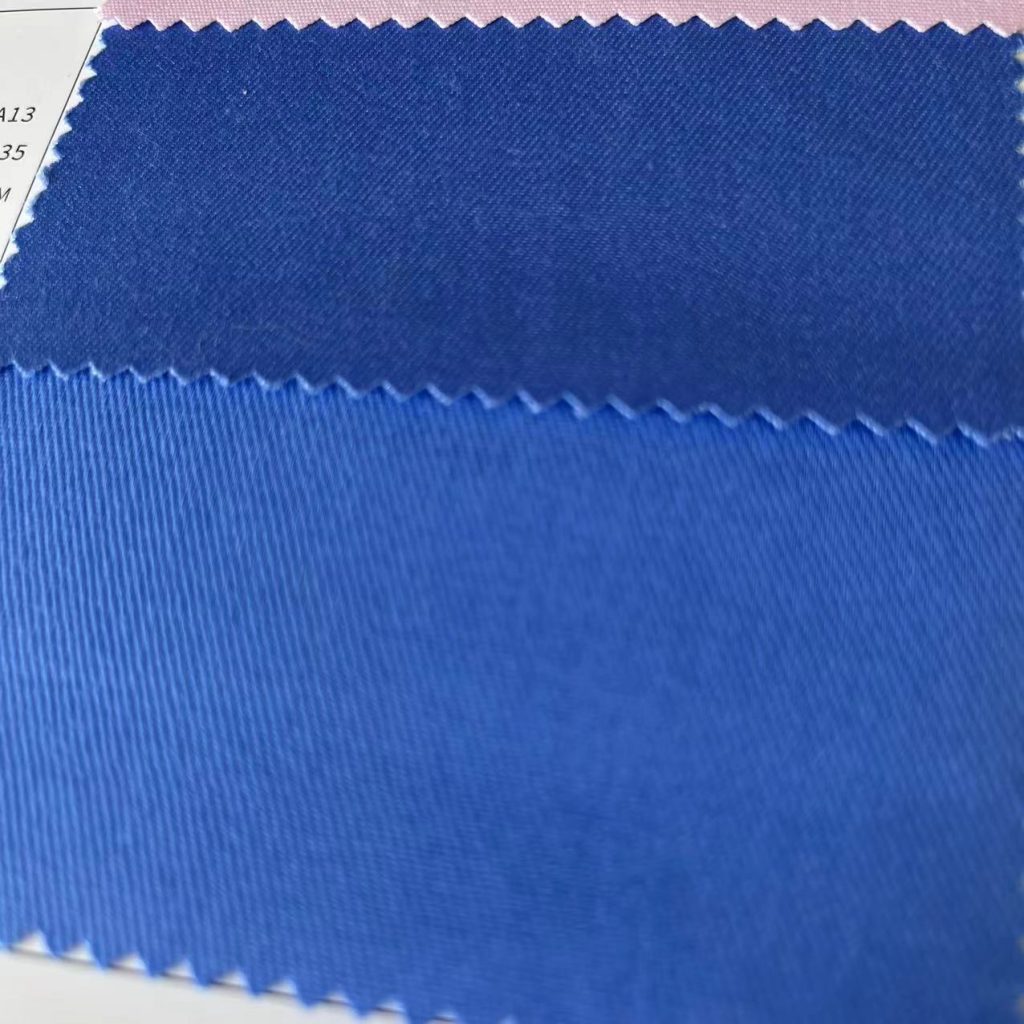

Based on our production experience, twill fabrics generally offer the best stretch, followed by plain weave fabrics. Smaller checkered patterns in checkered fabrics tend to have less effective stretch. Heavier fabrics may also struggle to achieve significant elasticity. These limitations are due to the structure and composition of the fabrics, which may not allow for the same degree of stretch as lighter, more flexible materials.

If you have specific needs, we recommend consulting with a fabric specialist who can help you determine the best application for your requirements. They can provide insights into the limitations and possibilities of mechanical stretch fabrics, ensuring you choose the right fabric for your project.

Summary

Mechanical stretch fabrics are a practical and sustainable alternative to spandex-blended fabrics. They provide comfort, durability, and versatility. By understanding the properties and benefits of mechanical stretch fabrics, you can make informed decisions for your next project.

For more information and specific inquiries, contact our fabric experts to find the perfect mechanical stretch solution for your project.

Further Reading on Mechanical Stretch Fabrics

- What are the Main Benefits of Mechanical Stretch Fabrics over Traditional Elastic Fabrics?

- Why Mechanical Stretch Fabric is the Ideal Choice for High-Performance Workwear

- What Makes Stretch Workwear Fabrics Ideal for Industry Professionals?

- Mechanical stretch fabrics: the future of flexible, durable and textiles