As regulations tighten globally around PFAS chemicals in textiles, fabric buyers face mounting compliance pressure. Traditional waterproof coatings may soon be obsolete. But a solution is rising fast — fluorine-free waterproof fabrics, combining sustainability with performance.

Fluorine-free waterproof fabrics offer a sustainable alternative to traditional coatings by avoiding PFAS. They reduce environmental harm, meet global compliance standards, and deliver effective water repellency — making them the ideal choice for forward-thinking buyers and brands.

Let’s explore why leading fabric buyers are shifting to fluorine-free options — and how you can stay ahead.

What makes a fabric truly waterproof?

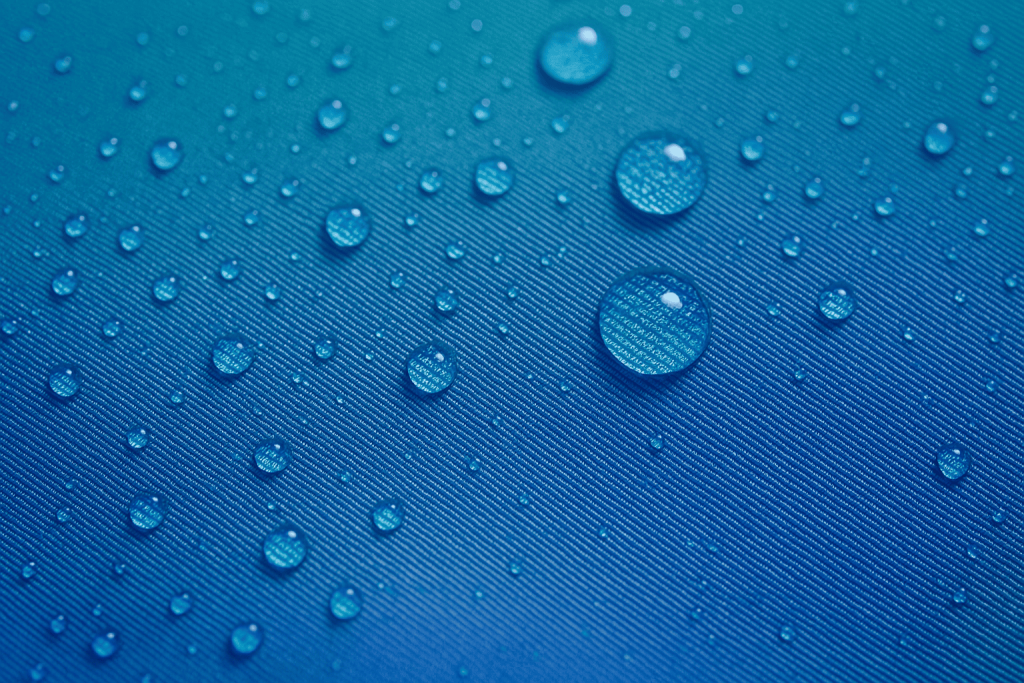

Waterproof fabric forms a barrier that blocks liquid water from passing through. Compared to water-repellent fabrics that merely resist light splashes, waterproof materials like Gore-Tex, polyurethane coatings, and laminated membranes offer full protection against rain, snow, or spills.

Fluorine-free waterproofing agents mimic this by modifying the surface energy of fabrics, often using acrylics, silicones, polyurethanes, or waxes. They form micro-barriers that bead water droplets off the fabric without relying on persistent fluorinated compounds.

How are fluorine-free waterproof fabrics made?

Modern fluorine-free finishes are the result of polymer innovation and surface science. There are four main technologies:

- Wax-based (low cost, but limited durability)

- Acrylic-based (balanced performance and handfeel)

- Silicone-based (soft touch, high breathability)

- Polyurethane-based (durable and strong adhesion)

Advanced approaches like side-chain orientation and bio-mimetic structures enhance repellency and durability. Some products even use bio-based components for better carbon footprint, such as Zelan R3 (63% renewable) or PalmDry (87%).

What regulations are driving PFAS bans in textiles?

Across the EU, U.S., and beyond, PFAS restrictions are rapidly expanding. Key policies include:

- EU REACH: PFOA, PFOS, and PFHxA bans

- Denmark 2025: Full PFAS prohibition in waterproof apparel

- California AB1817: PFAS-free requirement by 2025

- OEKO-TEX & Bluesign: Enforced total fluorine content limits

For fabric buyers exporting to Europe, compliance with PFAS-free standards is essential for market access.

What are the pros and cons of fluorine-free DWR?

✅ Pros:

- Safe for workers and consumers

- No environmental persistence

- Certifiable under major eco-labels

- Compatible with various fibers

⚠️ Cons:

- Lower oil repellency compared to C6/C8

- May require more frequent re-treatment

- Performance varies across applications

Which global brands are moving toward PFAS-free textiles?

| Brand | Action Plan |

|---|---|

| Nike | PFAS-free by 2020 across all supply chains |

| Adidas | 99% PFC-free by 2017, 100% by 2020 |

| Patagonia | Full switch by 2025 |

| Jack Wolfskin | 100% PFC-free since 2019 |

| Salomon | No PFAS in new gear by 2025 |

Where are fluorine-free waterproof fabrics used today?

- Outdoor gear (jackets, pants, tents)

- Workwear and uniforms

- Fashion & casualwear

- Home textiles (curtains, sofas)

- Footwear and bags

How does fluorine-free DWR perform in outdoor apparel?

Fluorine-free treatments now offer:

- Durable water repellency (up to 30 washes)

- Soft, natural handfeel

- Anti-marking and low color shift

- “Waterproof+” multi-functional solutions (anti-odor, anti-bacterial, UV-resistant)

What are the top eco waterproof fabric technologies?

- BIONIC-FINISH® ECO – High durability, fluorine-free

- Smartrepel® – Natural wax base

- PalmDry™ – 87% bio-content

- PU-Silicone blends – Soft + strong

- Side-chain orientation polymers – Biomimicry performance

Fluorine-free waterproof fabrics aren’t just eco upgrades — they’re your gateway to global compliance and long-term product sustainability.

Have questions about applications or sourcing? Reach out to our team for more info or sample support.