Introduction

With the rapid development of battlefield technology, military units around the world are upgrading their soldiers’ gear with high-performance fabrics. Traditional materials like pure nylon and polyester are being enhanced with abrasion resistance, waterproofing, anti-infrared (IRR) capabilities, and more. These specialized fabrics are used in everything from tactical vests and backpacks to rain gear and weapon covers. As the demands on soldiers and equipment continue to increase, the role of advanced, composite function fabrics has become essential in modern military applications.

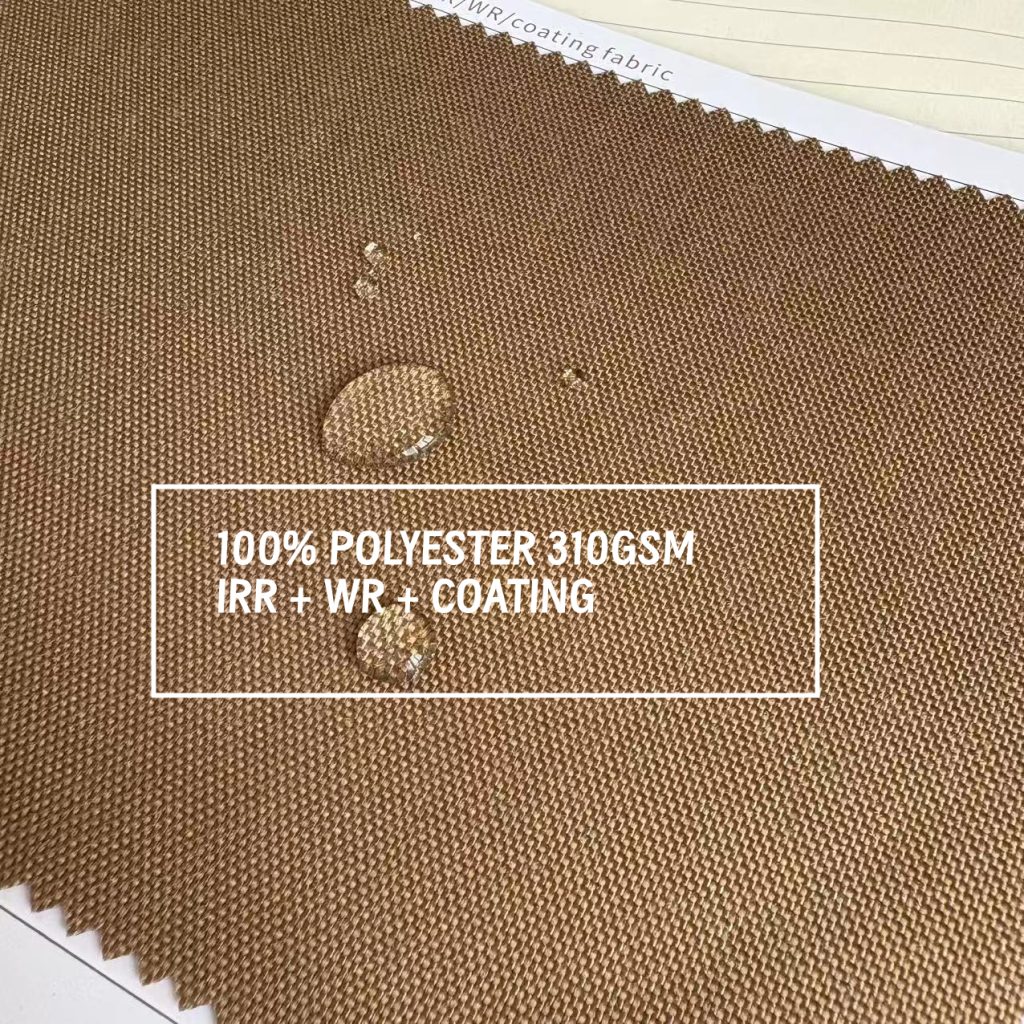

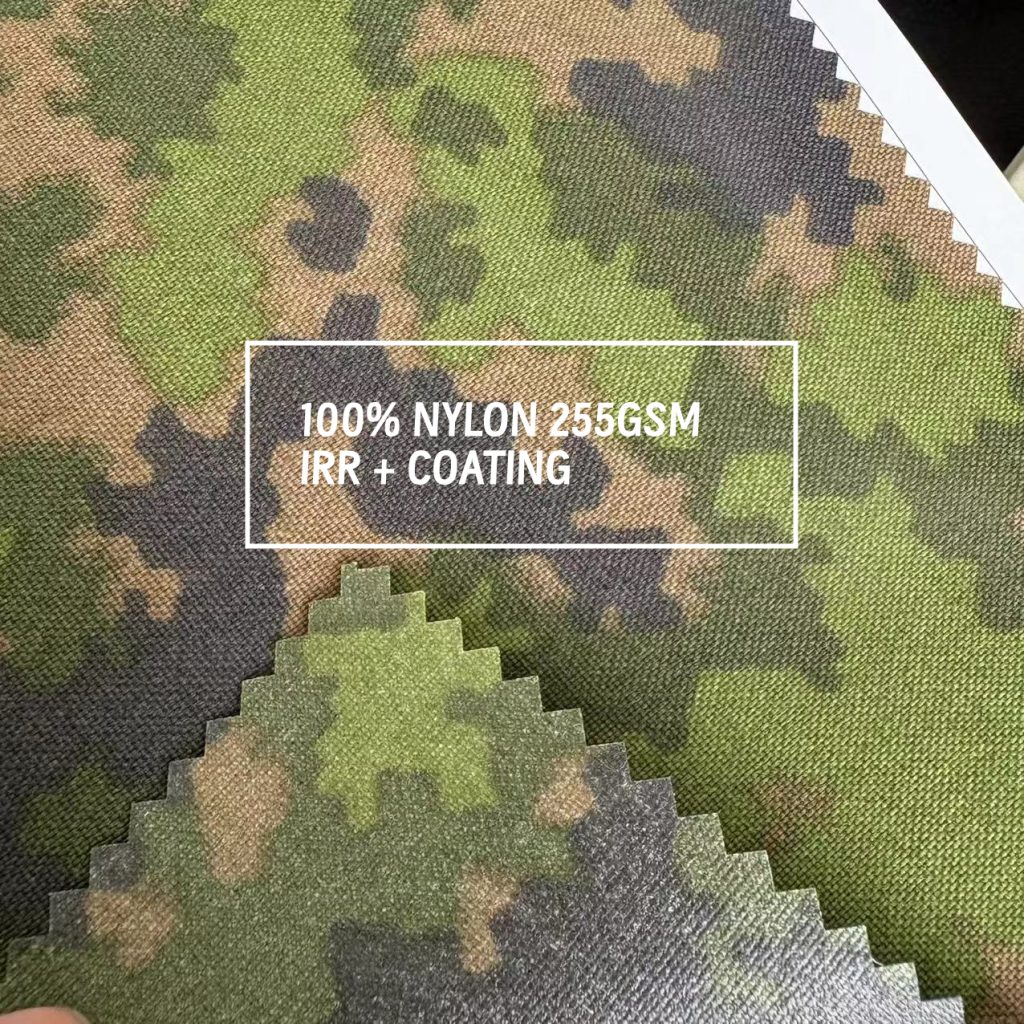

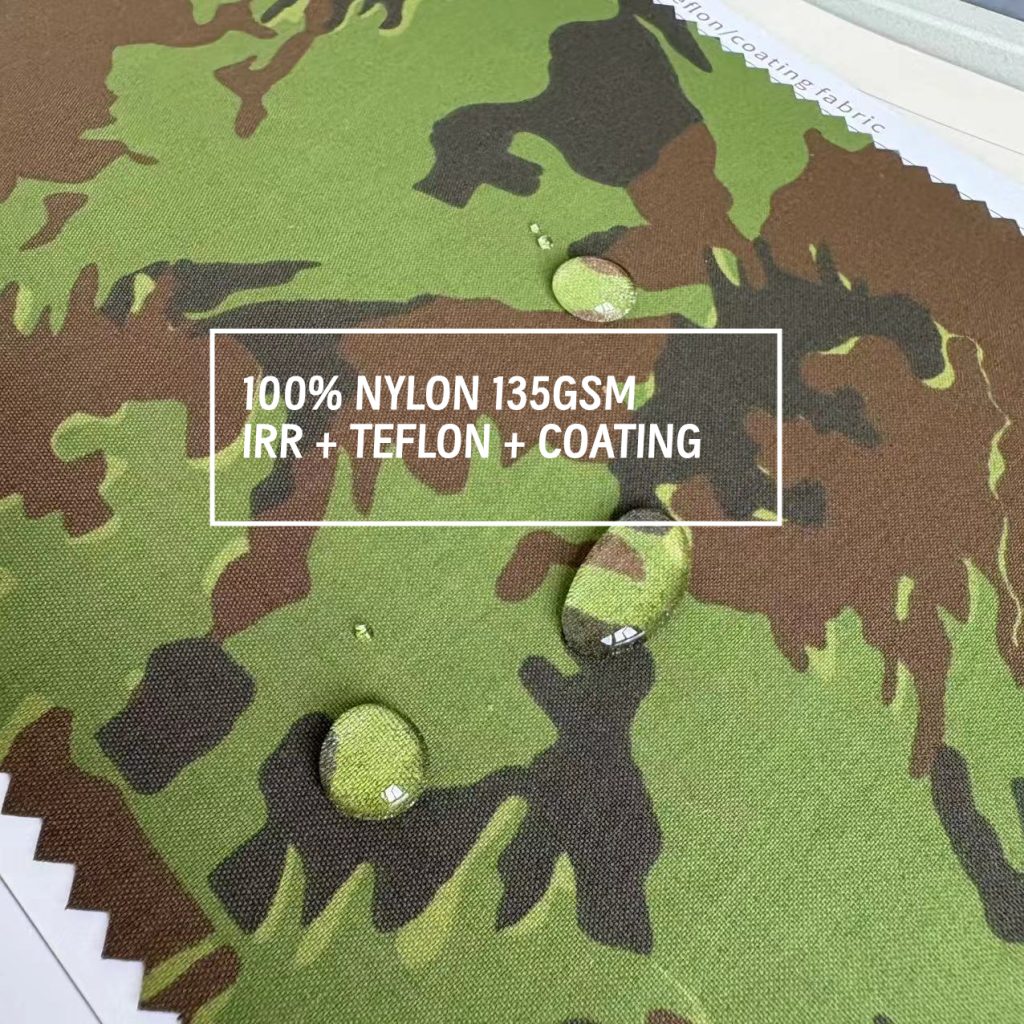

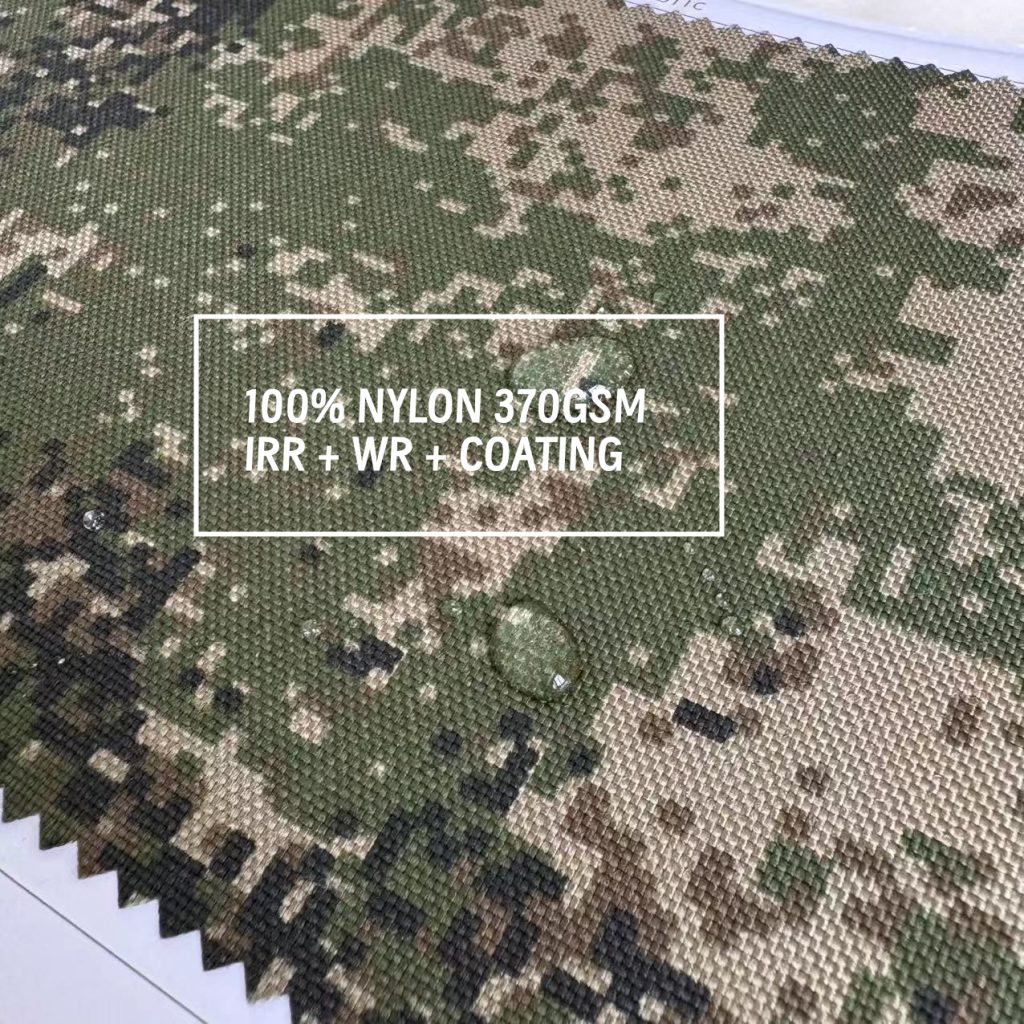

Key Takeaway: In this article, we’ll discuss the importance of combat equipment fabric and how our cutting-edge technology ensures durability and performance. At the bottom of this article, we will showcase some of the military fabric materials we commonly produce

The Role of Combat Equipment Fabrics in Modern Military Gear

As warfare evolves, so do the requirements for the equipment soldiers depend on. Gone are the days when basic materials sufficed for tactical gear. Today’s military units require fabrics that provide not only physical protection but also resistance to environmental elements and high-tech threats, such as infrared detection.

Modern tactical vests, bulletproof vests, backpacks, and raincoats are now being crafted from composite fabrics that incorporate both pure nylon and polyester, offering superior abrasion resistance and durability. These fabrics must withstand extreme wear and tear, which is why our materials are engineered to surpass one million abrasion cycles, ensuring the longevity and reliability that soldiers depend on.

Furthermore, weapon covers and camouflage materials now need to shield equipment from thermal detection while maintaining a high level of physical protection. Our fabrics are designed with these exact specifications in mind, making them a vital part of any military unit’s arsenal.

Advanced Technologies in Military Fabrics

What sets our military-grade fabrics apart is the integration of specialized composite technologies that enhance performance across multiple categories. Here’s a look at some of the key technologies:

- Abrasion Resistance: Our fabrics are tested to withstand over 1,000,000 abrasion cycles. This ensures that even in the harshest conditions—whether it’s crawling through rocky terrain or carrying heavy loads—your tactical gear remains in top shape.

- Cold Resistance: One of the standout features of our fabrics is their ability to withstand freezing temperatures. With coatings that remain flexible and crack-free at temperatures as low as -40°C, you can rely on your gear no matter where your missions take you.

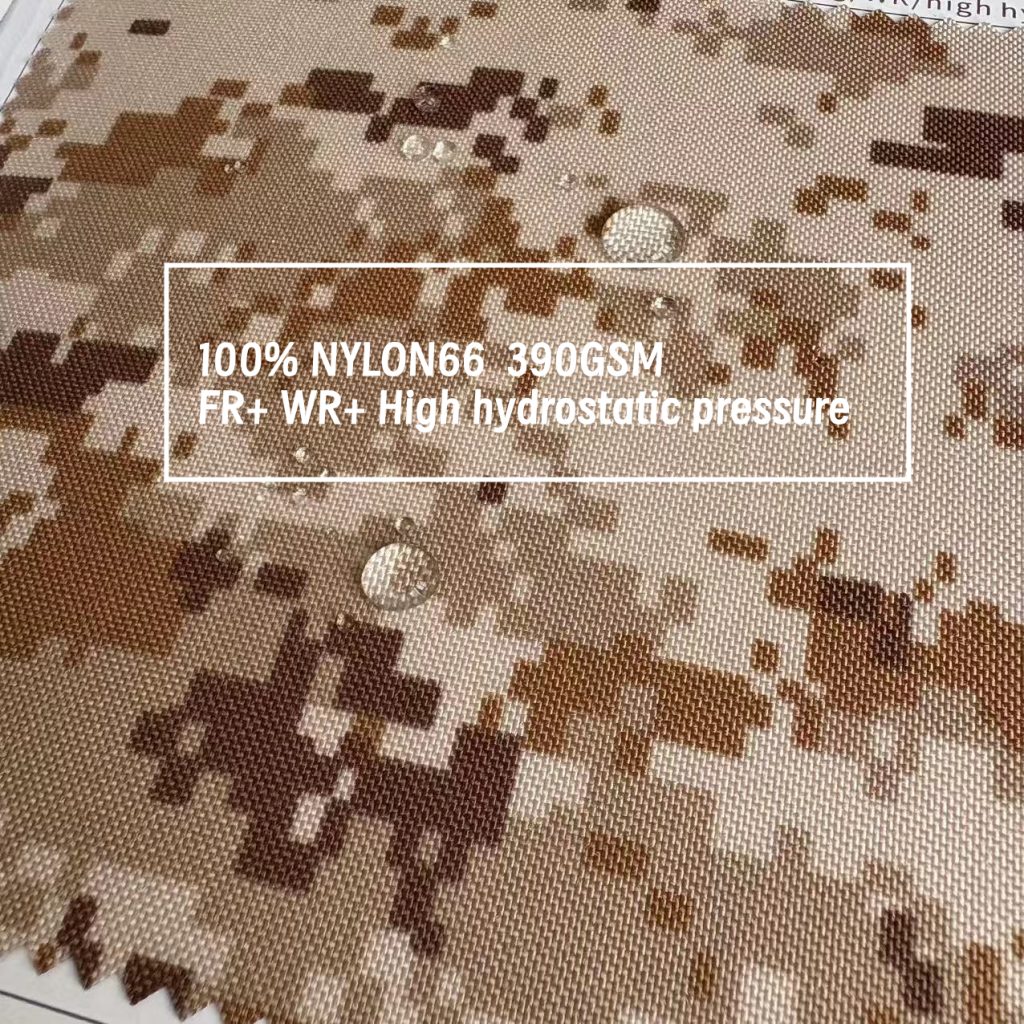

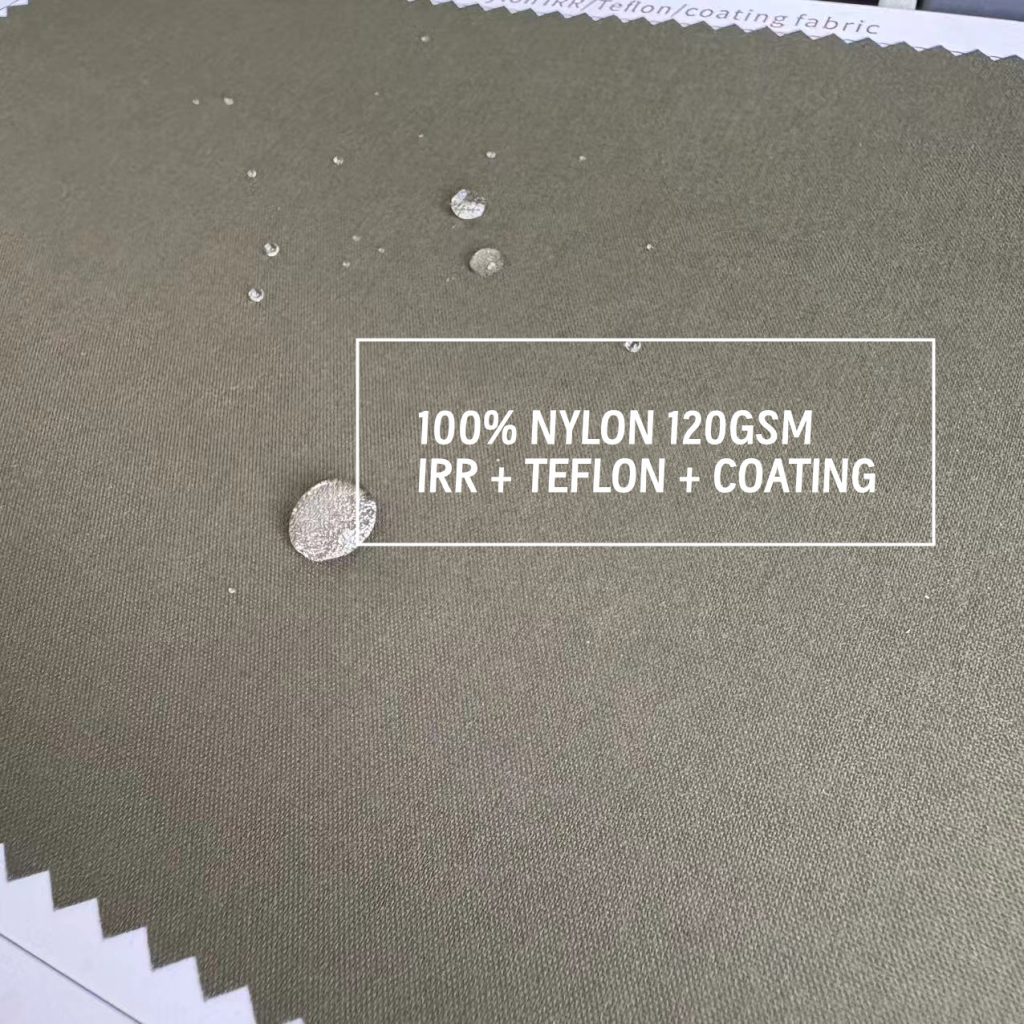

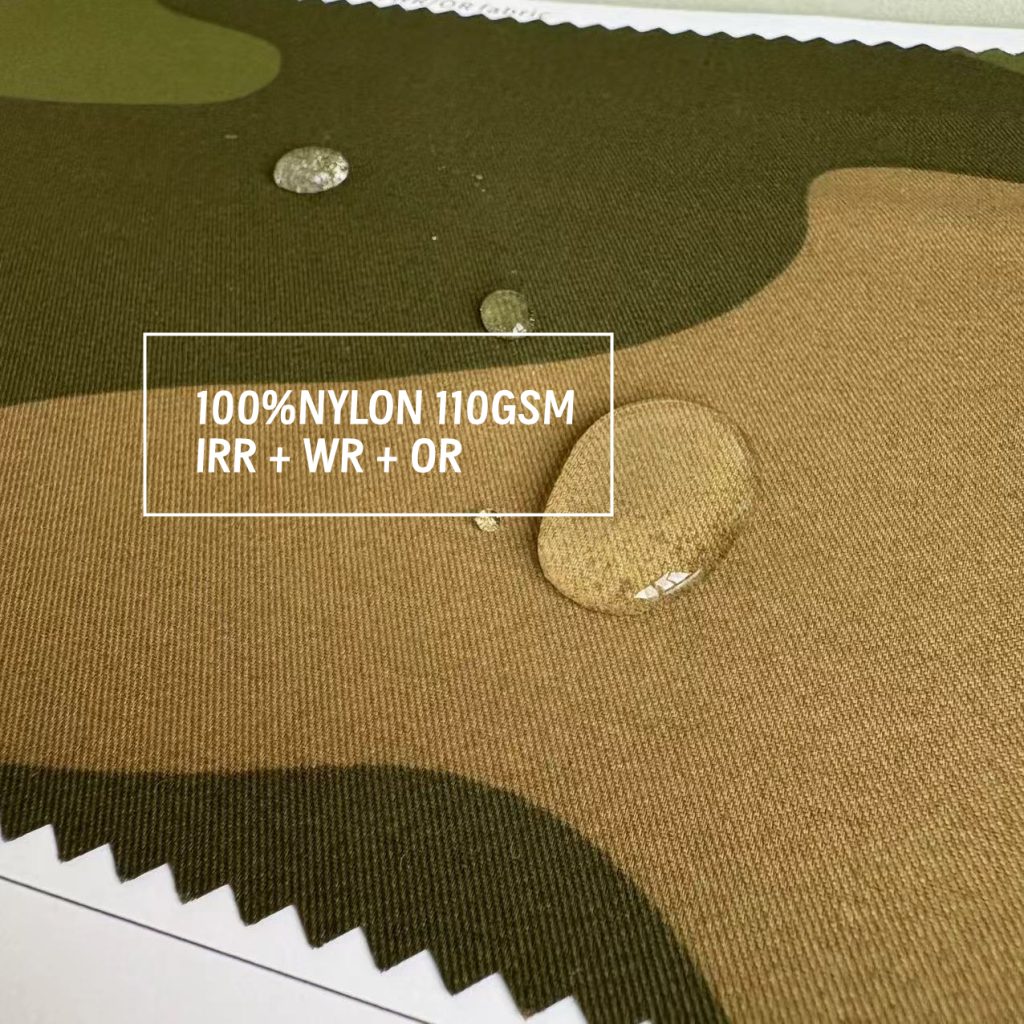

- Waterproofing & Windproofing: Staying dry in the field is crucial. Our fabrics boast high hydrostatic pressure resistance, ensuring that raincoats, tents, and backpacks keep water out, even during downpours. They also provide wind resistance to keep you warm and protected in harsh environments.

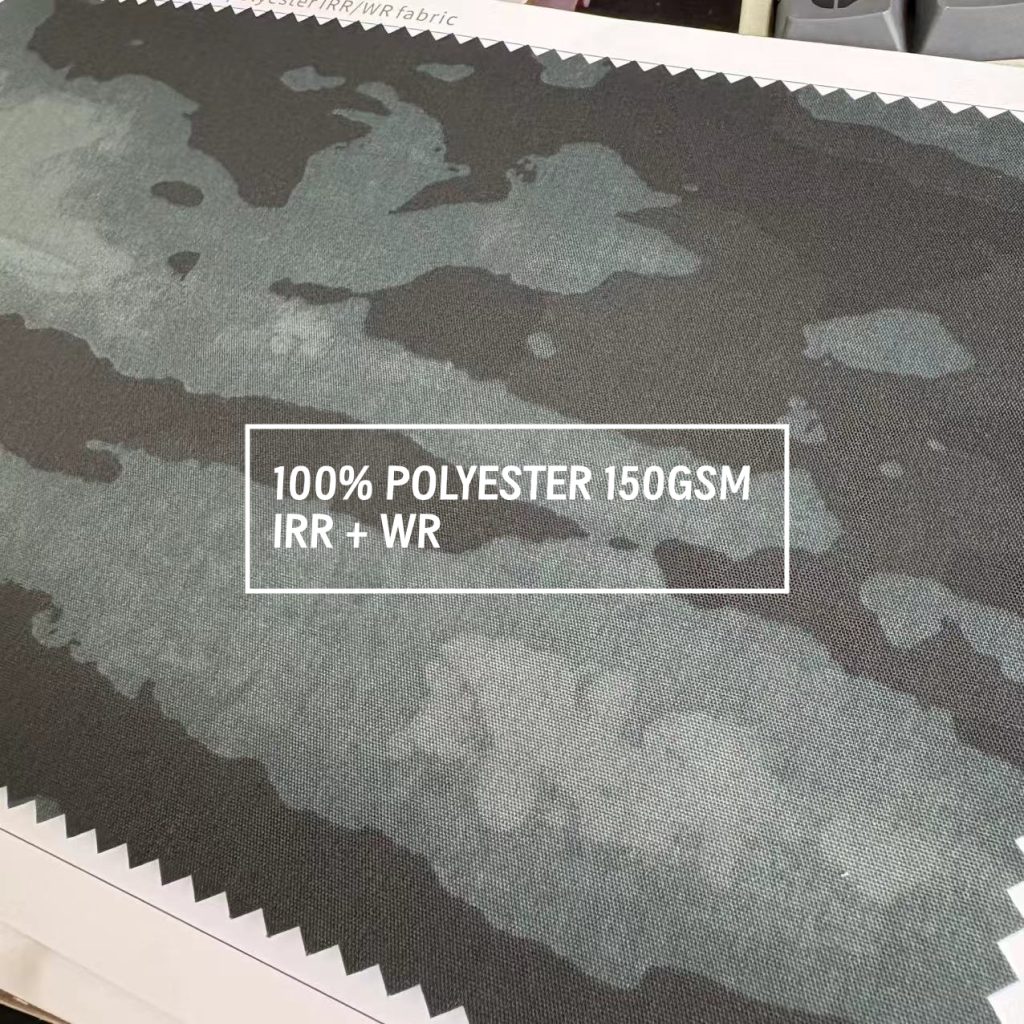

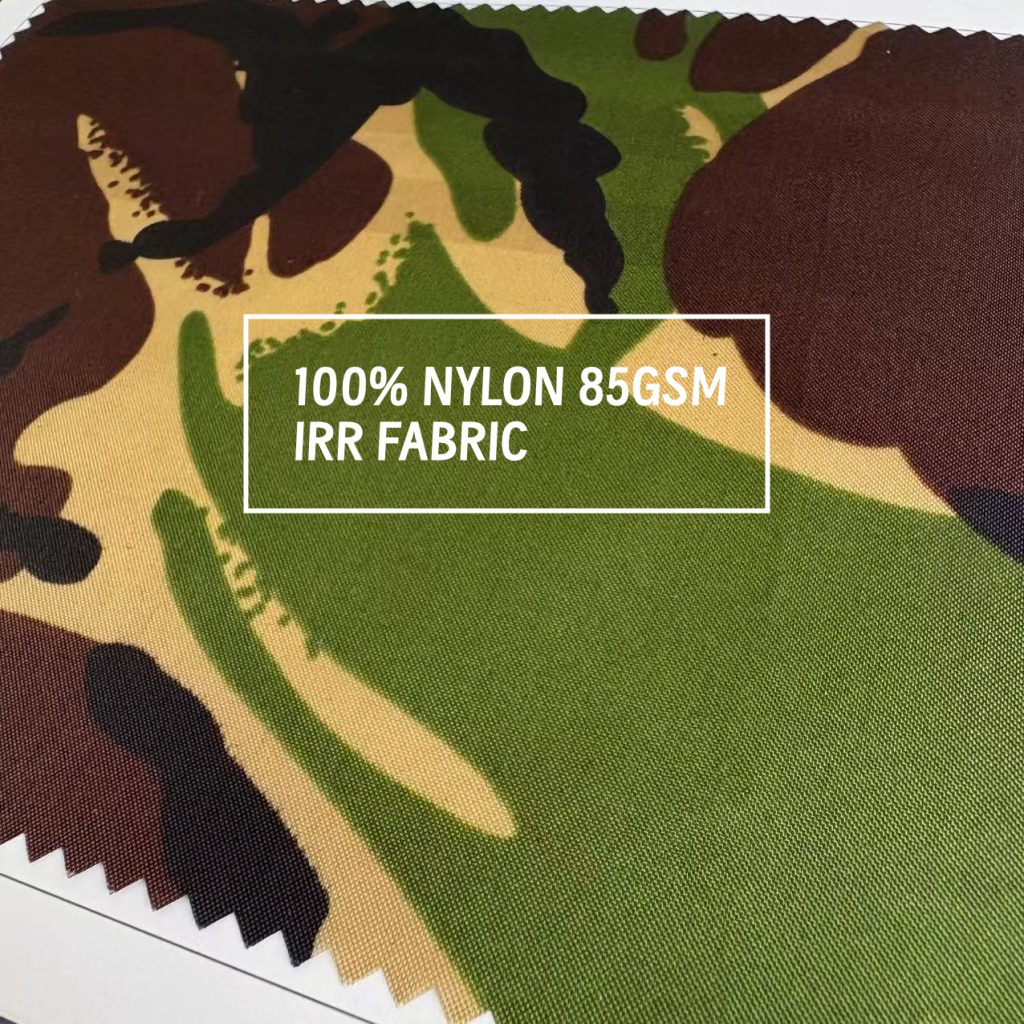

- Infrared (IRR) Protection: One of the most advanced features of our fabrics is their anti-infrared capabilities. This technology reduces heat signatures, helping you stay undetected by enemy infrared sensors. In modern warfare, this can mean the difference between life and death.

- Anti-Mosquito & Anti-Bacterial Treatments: For missions in tropical environments, our fabrics come with anti-mosquito and anti-bacterial treatments, keeping you safe from insect-borne diseases and maintaining hygiene even in humid, wet conditions.

- Fire Resistance and Anti-Thermal Imagery: Fabrics for weapon covers are designed with flame retardant materials and anti-thermal imagery technology, ensuring that your weapons and gear stay hidden from thermal sensors while remaining safe from fire hazards.

Ensuring Quality with Top-Notch Materials and Partnerships

Quality is everything. We use branded fibers and top materials to make our fabrics. We work with companies like DuPont, a world leader in fibers, to ensure we meet high standards. We make sure our fabrics are better than what’s expected in the military. We use the right stuff and make it the right way.

- Colorfastness: Our fabrics are rated 5-6 for colorfastness. That means the colors won’t fade. They’ll stay bright and effective no matter what conditions soldiers face. Whether it’s bright sunlight or heavy rain, the colors will stay true.

- High hydrostatic pressure: Our fabrics are designed to resist high water pressure. That means they’re ideal for gear like raincoats, tents, and sleeping bags. Soldiers stay dry and comfortable no matter what the weather.

Endless Customization: Thousands of Camouflage Patterns to Choose From

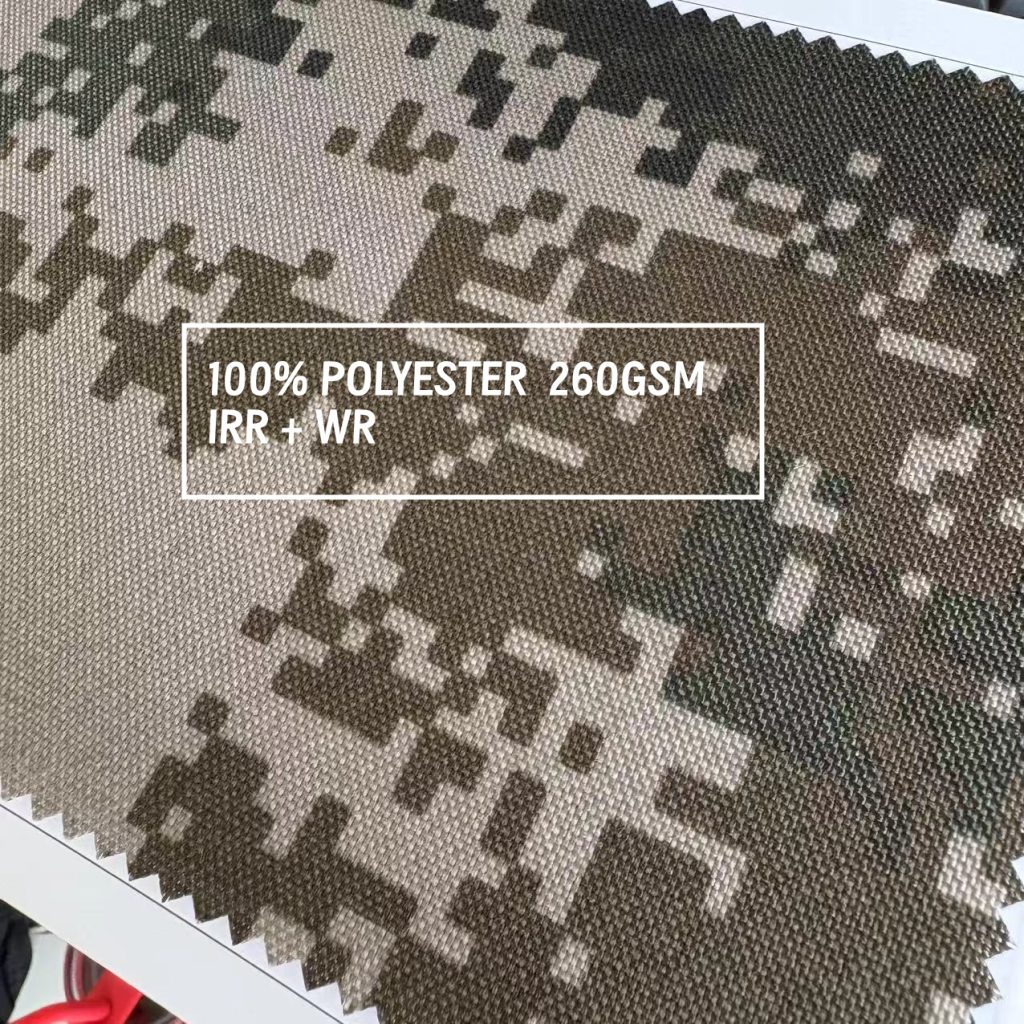

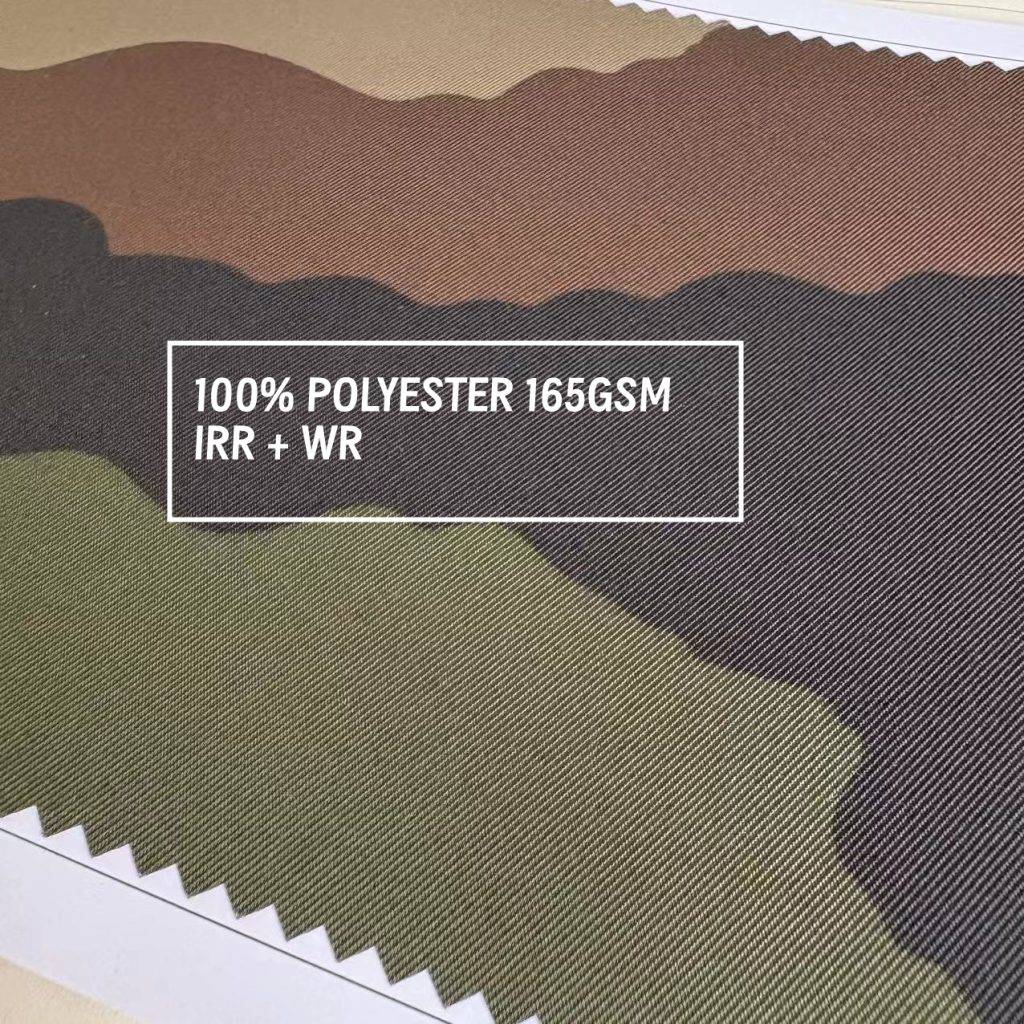

We have thousands of camouflage patterns to choose from. We know one size doesn’t fit all. Different military units have different needs based on where they operate. We have patterns for the desert, jungle, urban environments, and more. If you need something unique, we can create a custom pattern for you. Our camouflage fabrics not only work visually, but they also reduce thermal signatures. That means it’s harder for the enemy to spot soldiers or equipment with heat sensors.

Conclusion

Our combat equipment fabrics give soldiers the durability, protection, and advanced technology they need to perform in today’s high-stakes environments. From abrasion resistance to the latest anti-infrared technology, we have the fabrics that give soldiers a tactical advantage. We have thousands of camouflage patterns and customization options. We make sure your gear works and looks the way you want. Work with us and get the best fabrics to keep your soldiers safe, comfortable, and mission-ready.

Call to Action: Contact us today to learn more about our full range of military fabrics and to request samples.