In the industrial laundry sector, the ability of a fabric to withstand repeated washing, high temperature, chemicals, and mechanical force determines how long a garment can be worn — and whether customers reorder.

This article summarizes our 50-cycle industrial washable fabrics, 70-cycle industrial washable fabrics, and industrial washable stretch fabrics, with full specifications for easy comparison.

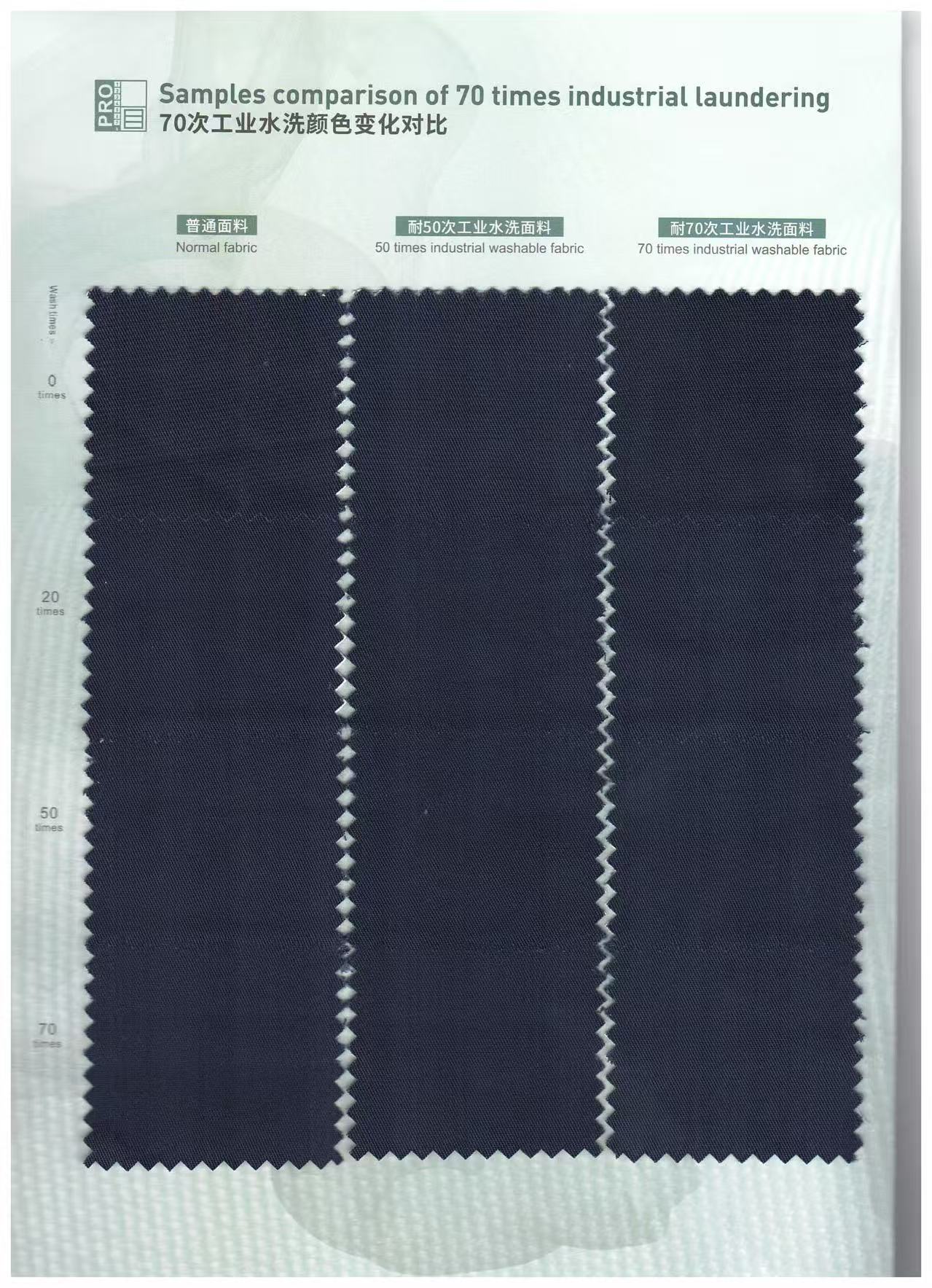

1. 70-Cycle Industrial Washing: Color Change Comparison

This is the core comparison, showing normal fabric, 50-cycle washable fabric, and 70-cycle washable fabric after industrial laundering.

Note: Due to photo lighting, the color difference may not appear very obvious in the picture — but in real testing, the contrast is clear.

Key observations:

- Normal fabric shows significant fading

- 50-cycle washable fabric is more stable

- 70-cycle washable fabric shows the least color change, almost no fading or whitening

Ideal for:

- Industrial laundry services

- Workwear rental companies

- Hospitals, hotels, cleaning & maintenance

2. Industrial Wash + Multiple Functional Options

Functions can be combined with industrial washability:

- Stretch (spandex or mechanical stretch)

- Water / Oil / Soil Repellent (WR/OR/SR)

- Inherent FR

- Anti-static (EN 1149-1/-3)

- Soil Release

- Anti-bacterial / Anti-virus

- 95°C high temperature washing

Applicable industries:

- Catering, kitchen & food service

- Automotive & maintenance

- Oil & gas, petrochemical

- Electronics manufacturing

- Medical & healthcare

- Outdoor work

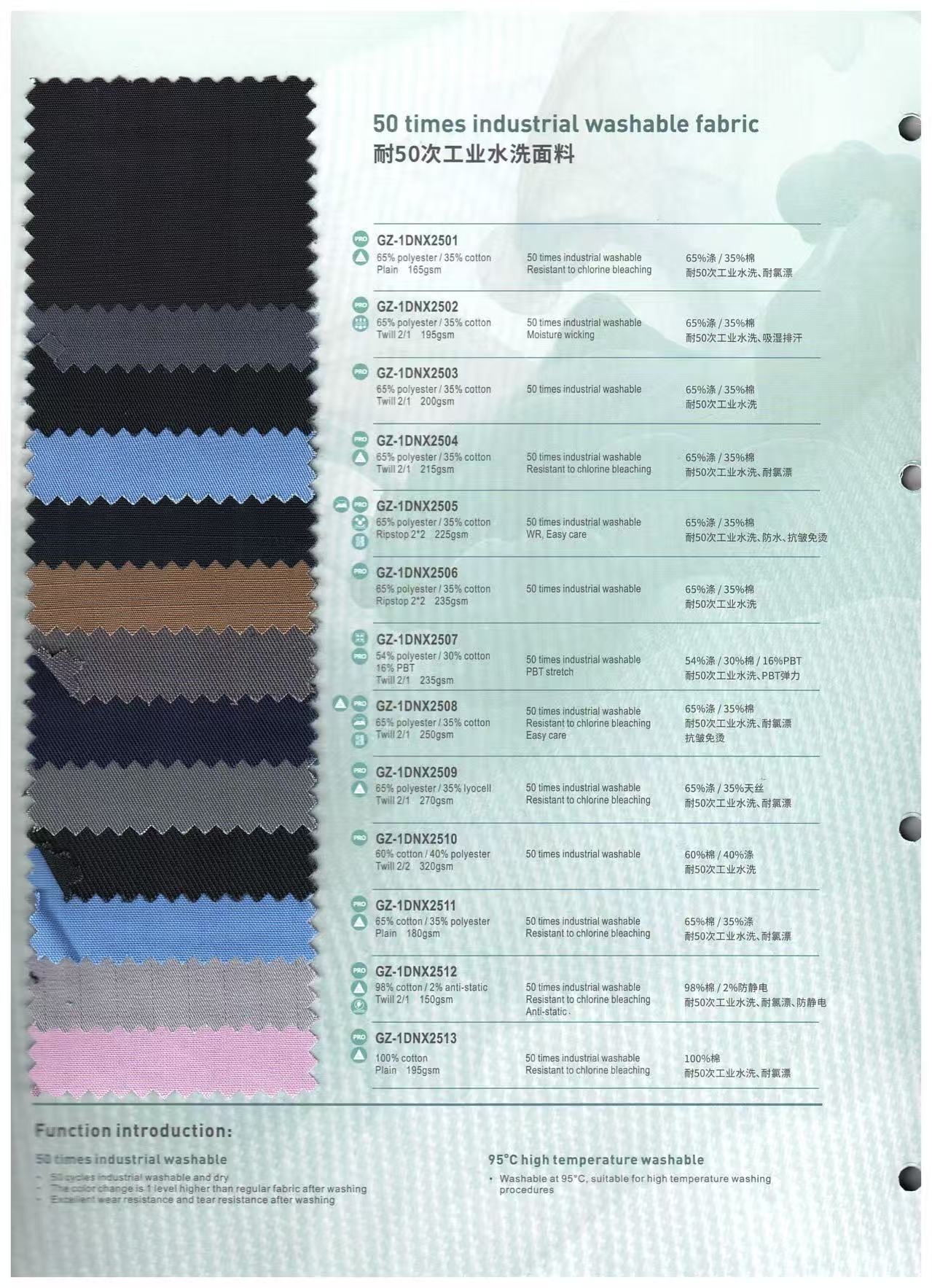

3. 50-Cycle Industrial Wash Fabrics (Specifications)

Specification Overview

Highlights:

- Color fastness 1–1.5 grades higher than regular fabrics

- Excellent tear & abrasion resistance

- Suitable for 95°C washing

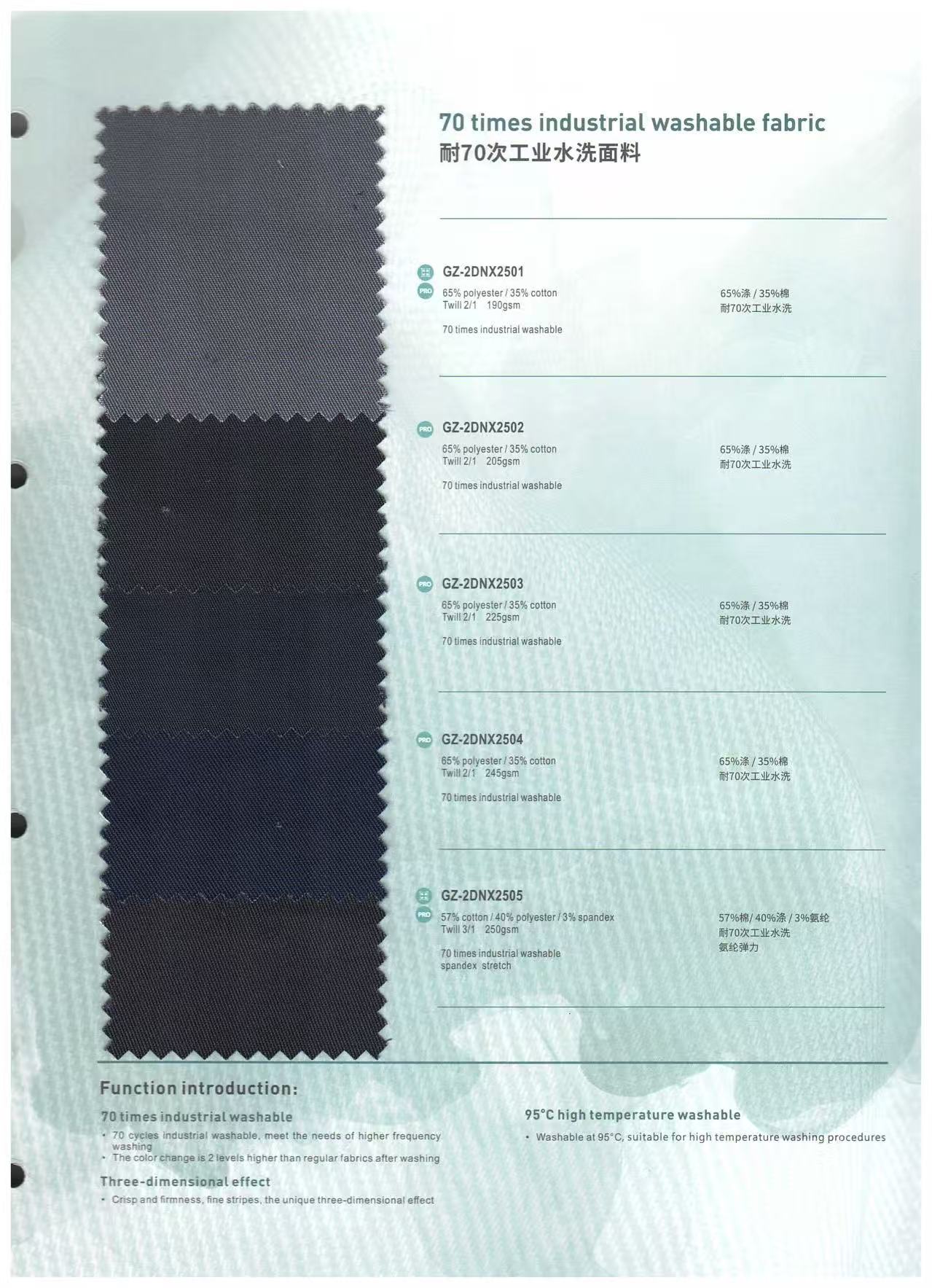

4. 70-Cycle Industrial Wash Fabrics (Specifications)

Highlights:

- Minimal color change after 70 industrial washes

- Only 1/3 the color change compared to standard TC fabric

- Higher yarn strength retention

Ideal for high-frequency industrial washing environments.

5. Industrial Wash Stretch Fabrics (160°C Tunnel Drying)

Why they are special:

- High-temperature resistant elastic fiber

- Still maintains stretch after 50 washes + 160°C drying

- Versus regular spandex:

- Elastic damage: ≤ 10%

- Regular spandex: 50–60%

Perfect for factories that use tunnel dryers.

6. Applications

These fabrics are ideal for:

- Workwear rental companies

- Catering & kitchen uniforms

- Medical & healthcare

- Hospitality & laundry services

- Maintenance & automotive

- Cleaning service providers

- Oil, gas & chemical industries

Industrial washable fabrics significantly extend garment lifespan and reduce replacement cost.

7. Inquiry

If you have related requirements and need fabrics for industrial washing, just tell us what you need — we will provide the solution.

Contact:

- 📧 sales@ripstopfabric.com

- 🌐 https://ripstopfabric.com