A European workwear brand faced severe color fading and pilling in their navy ripstop pants after industrial washing. We helped them uncover the root cause and recommended the right fabric solution—saving their reputation and long-term costs.

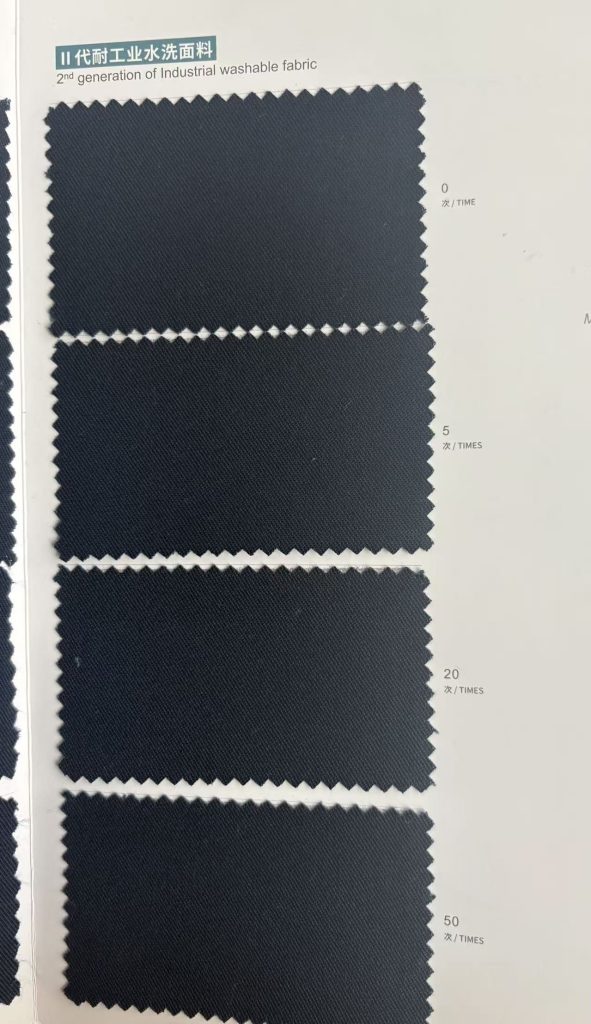

To solve colorfastness issues in dark ripstop pants, we worked with the client to analyze their washing process—revealing the use of industrial laundry at 60–75°C with bleach. We recommended a fabric tested under ISO 15797, engineered for industrial washing. After 50 wash cycles, the new fabric retained colorfastness grade 4 and a clean, crisp surface.

Let’s break down the problem, the process, and how we reached a fabric that lasts 50 industrial washes without fading.

The Problem: Fading and Pilling in Navy Ripstop Pants

One of our long-term European clients—a reputable workwear brand—reached out with an urgent concern.

Workers had reported that their navy-colored ripstop pants were losing color rapidly, fading into a reddish tone. The surface had also become fuzzy and showed heavy pilling. This was more than a cosmetic issue—it was damaging the company’s brand image and trust.

The pants were made of 65% polyester / 35% cotton, 245gsm, a common spec in workwear. At first glance, the fabric looked fine. But under repeated use, its weaknesses were quickly exposed.

Diagnosis: Understanding Industrial Laundry Conditions in Europe

To investigate the issue, we engaged in detailed communication with the client. Through email and technical Q&A, we uncovered a key operational difference:

Unlike in China, where many workers wash their uniforms at home, this European client used professional laundry companies to clean their workwear.

These commercial laundries follow industrial washing standards, typically:

- Water temperature between 60–75°C

- High-frequency wash cycles

- Use of detergents containing mild bleaching agents like sodium hypochlorite (NaClO)

The original fabric had not been engineered to endure such harsh washing conditions. Standard dyed polyester-cotton fabrics, especially dark colors like navy, are prone to fading, fiber damage, and surface fuzzing when exposed to industrial laundering.

The Solution: Switching to ISO 15797-Compliant Fabric

We advised the client to switch to fabrics specifically tested and approved for industrial laundering under ISO 15797—the global standard for workwear fabrics under repeated high-temperature, high-chemical washes.

Our in-house lab provided:

- Strike-off samples in dark navy using reactive + disperse dyeing techniques

- Lab test reports referencing ISO 105-C06 color fastness to washing

- Surface abrasion resistance and pilling resistance data

We also applied additional treatments for:

- Anti-pilling

- Chlorine-resistance

- Durable dimensional stability

The results:

- After 50 industrial wash cycles, color change remained at grade 4

- Fabric surface stayed clean, structured, and smooth

- The ripstop weave remained clearly defined, with no visible softening or collapse

👉 See how to choose and maintain industrial laundry fabrics

👉 Explore the best industrial laundry fabrics for workwear

Why It Matters: Protecting Brand Image and Long-Term ROI

In the workwear industry, fabric quality goes beyond performance—it represents your brand. Faded, fuzzy garments reflect poorly on companies, especially in sectors like security, maintenance, and logistics.

By investing in ISO 15797-compliant fabrics, the client:

- Reduced product complaints

- Improved uniform consistency and durability

- Maintained a strong, professional brand image

- Lowered long-term replacement and maintenance costs

While the cost of industrial-washable fabric is slightly higher, the returns in quality and brand trust are well worth it.

Colorfast fabrics are more than just technical specs—they’re brand protection. Need help choosing the right material for industrial washing? Let’s talk.