When buyers discuss tear resistant fabric for construction work pants, the conversation often starts with fabric structure or lab test data.

In real projects, however, fabric problems usually appear much earlier — at the stage of understanding how the pants will actually be used. Many durability issues are not caused by poor-quality materials, but by fabric choices that do not match real working conditions.

In construction workwear, tear resistance is not a single feature. It is the result of fabric weight, weave, yarn quality, stretch system, and washing method working together.

Start with the Real Working Environment

Construction work pants are exposed to continuous stress: kneeling, climbing, friction at the knee and seat areas, and frequent contact with tools. Whether the garments are industrially laundered or home washed also changes fabric requirements significantly.

In several construction projects, fabrics that looked fine on paper still failed early because these real conditions were underestimated.

Fabric Weight Is Often Underestimated

For construction work pants, lighter fabrics may look attractive on specifications, but they often lack long-term durability.

In practice:

- Fabrics below 220 gsm usually carry higher risk

- 240–260 gsm works better for medium-duty construction

- 280–300 gsm is safer for heavy-duty environments

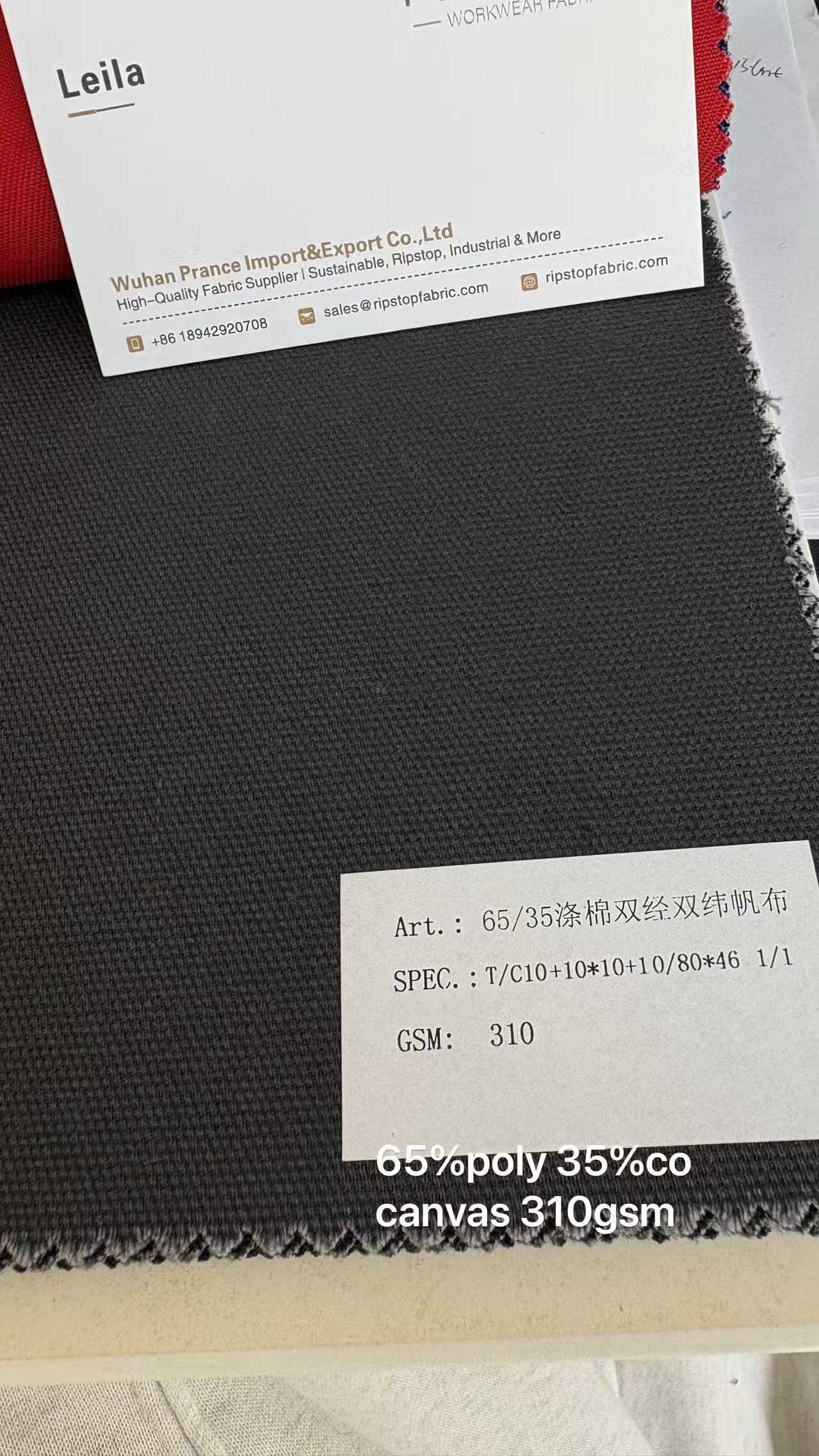

Example: Heavy Canvas Fabric

A 65% polyester / 35% cotton canvas around 310 gsm is commonly used for heavy-duty construction work pants, especially in autumn and winter. The dense structure provides strong resistance to tearing and abrasion, making it suitable for high-wear areas where durability is the priority.

Ripstop Is a Tool, Not a Guarantee

Ripstop is often assumed to be the best solution for tear resistance, but this is not always the case.

Ripstop fabric is designed to prevent tearing from spreading, not to prevent tearing from starting. In construction work pants, repeated friction and pressure often damage yarns before a clean tear even forms.

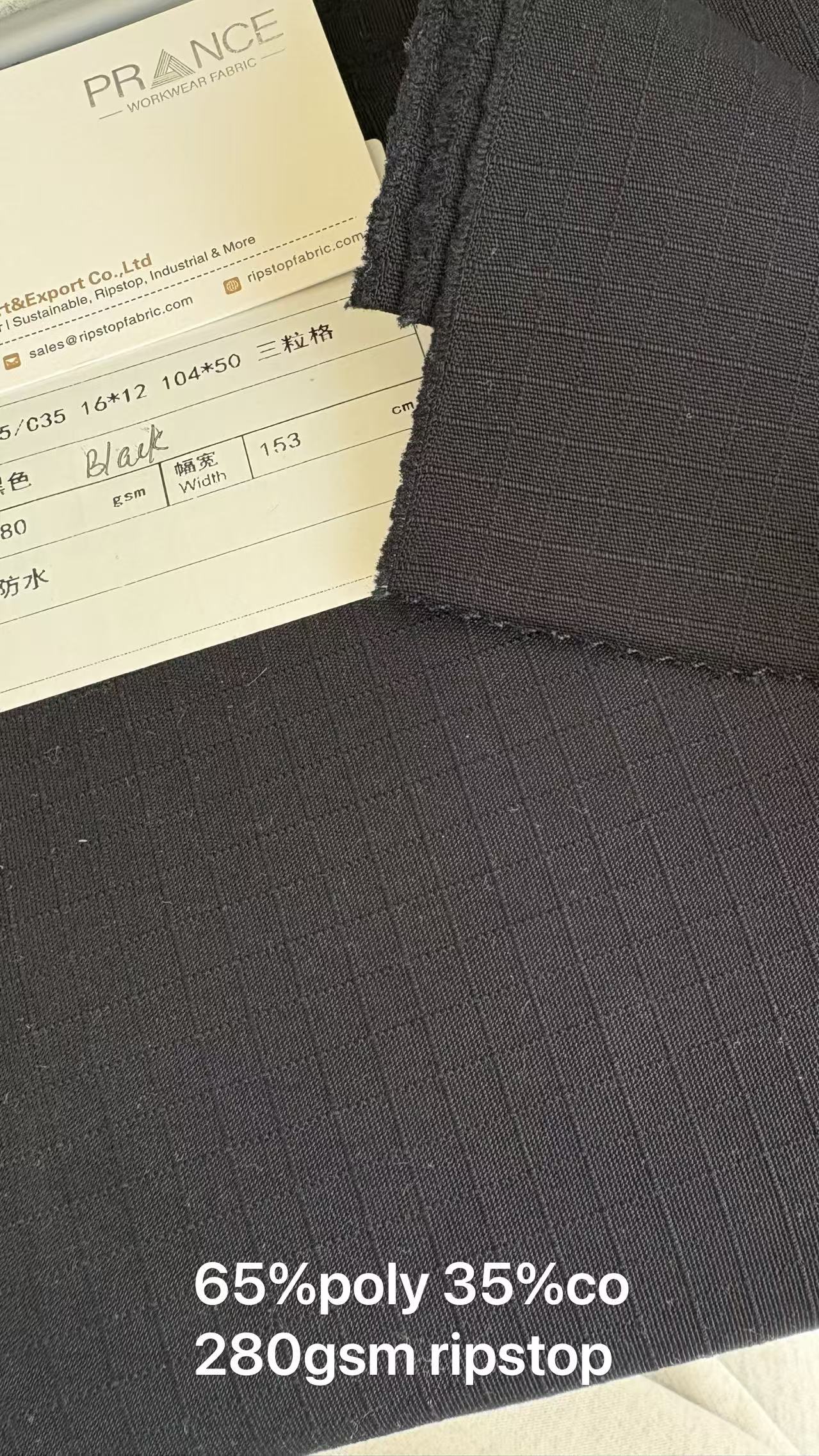

Example: Heavy Polyester-Cotton Ripstop

A 65% polyester / 35% cotton ripstop around 280 gsm performs better than lightweight ripstop because the base fabric itself already provides strength. The ripstop grid helps control tearing under local stress instead of relying on structure alone.

Yarn Quality and Fabric Structure Still Matter

Two fabrics with similar weight and composition can behave very differently due to yarn quality, spinning method, and weave stability.

This is why fabrics that look similar can show very different tear strength results in both testing and real wear.

Stretch: Comfort Needs to Be Controlled

Stretch improves comfort and mobility, which is important for construction workers. However, durability can be compromised if the stretch system is not suitable for workwear conditions.

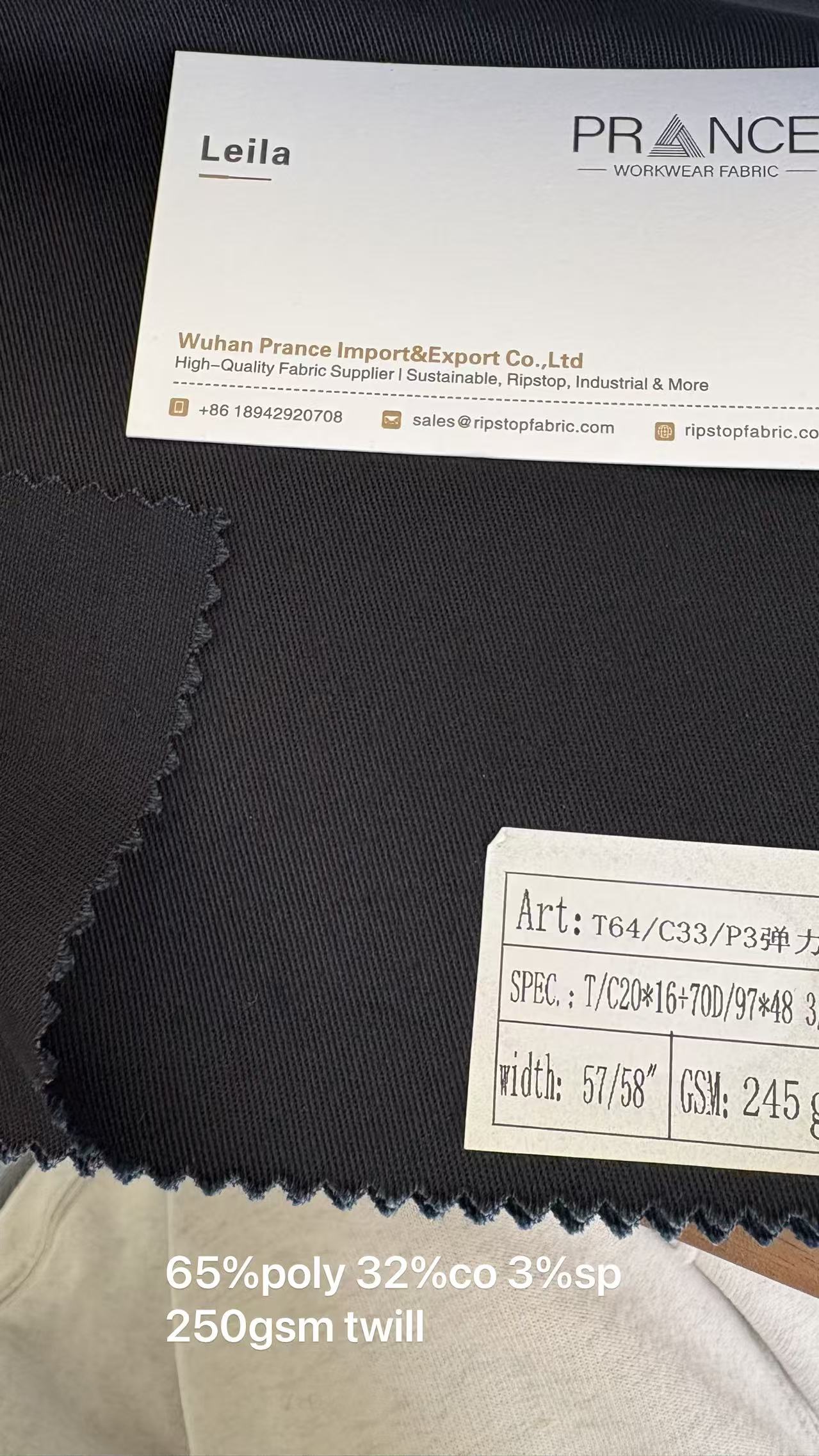

Example: Stretch Poly-Cotton Twill

A 65% polyester / 32% cotton / 3% spandex twill around 250 gsm is one of the most common fabric choices for work pants. It offers a practical balance between durability and flexibility and is often combined with water- and oil-repellent finishes, such as Teflon, to improve everyday performance.

Lab Tests Help, but Real Use Decides

Tear strength test results are useful, but they cannot fully simulate real wearing conditions.

For longer-term or tender-based projects, small trial runs often reveal issues that lab data alone cannot predict. This approach may feel slower at the beginning, but it usually prevents bigger problems later.

Final Thoughts

Choosing tear resistant fabric for construction work pants is about matching fabric design with real use.

Fabric weight, weave structure, yarn quality, stretch system, and washing method all need to align with the working environment. There is no single fabric that fits every construction project.

Tear resistance is not achieved by one feature alone.

It is built through many small, correct decisions made early in fabric selection.

When those decisions are based on real working conditions rather than assumptions, work pants perform better — not only in tests, but on real job sites.