Ripstop fabric is everywhere—from rugged mountain jackets to sleek city utility wear. But how can one textile serve such different markets? The answer lies in how brands shape their narrative around function and form.

Ripstop is a tear-resistant woven fabric used across outdoor, streetwear, and workwear markets. Its durability, lightweight feel, and water resistance allow it to be adapted for extreme environments, fashion-forward silhouettes, and industrial-grade uniforms alike. It’s a single fabric with multi-market versatility.

Let’s explore how ripstop adapts to these three fashion and function-driven worlds.

What Is Ripstop Fabric and Why It Matters in Performance Wear?

Ripstop is a technical woven fabric distinguished by its grid-like weave pattern, where thicker reinforcement yarns are interwoven at regular intervals. This pattern helps stop small tears from spreading—hence the name "rip-stop."

Originally developed for military and parachute applications, ripstop has evolved into a key textile in performance outerwear, uniforms, and utility wear. Depending on the fiber used—nylon, polyester, cotton blends, or T400 spandex—ripstop fabrics can offer a wide range of benefits:

- Tear and abrasion resistance

- Water repellency and stain resistance

- Breathability

- Mechanical stretch (when using spandex or T400)

- Colorfastness and wash durability

For workwear applications, fabrics such as this 220gsm T400 spandex ripstop offer both flexibility and ruggedness, making them suitable for uniforms requiring stretch and structure.

Learn more from our in-depth guide on ripstop applications in workwear.

Outdoor Performance: How Ripstop Serves the Adventure Market

In outdoor apparel, function is king. Brands like Columbia, Patagonia, and Arc’teryx rely on ripstop to create garments that can withstand harsh weather, physical stress, and daily movement. While synthetic ripstop (like nylon or polyester) is popular for ultralight gear, cotton-based ripstop is increasingly favored for its comfort and natural feel.

A prime example is the Columbia Loma Vista™ III Jacket, which uses a 60% cotton / 40% polyester ripstop shell. This blend provides the rugged look and tactile warmth of cotton, with added tear resistance and weather performance from polyester.

Columbia Loma Vista™ III Jacket – Cotton-Poly Ripstop Shell

This example shows that ripstop isn’t just for synthetic-heavy hiking jackets—cotton blends offer a comfortable, durable option for cool-weather outdoor wear with a casual aesthetic.

Outdoor brands often highlight features like:

- Wind-resistant ripstop outer shells

- Durable cotton-polyester blends for softness + performance

- Coated or lined interiors for added water repellency

- Strong seams and reinforcements for abrasion zones

Urban Utility Wear: Ripstop’s Aesthetic in the City

Ripstop is not only for survival—it’s also become a style statement in urban fashion and "gorpcore." Labels like Carhartt WIP, Acronym, Guerrilla-Group, and Nike ACG incorporate ripstop fabrics in ways that blend utility with aesthetic.

Beyond just visual utility, modern urban workwear is demanding more flexibility and comfort, which is where stretch ripstop becomes essential.

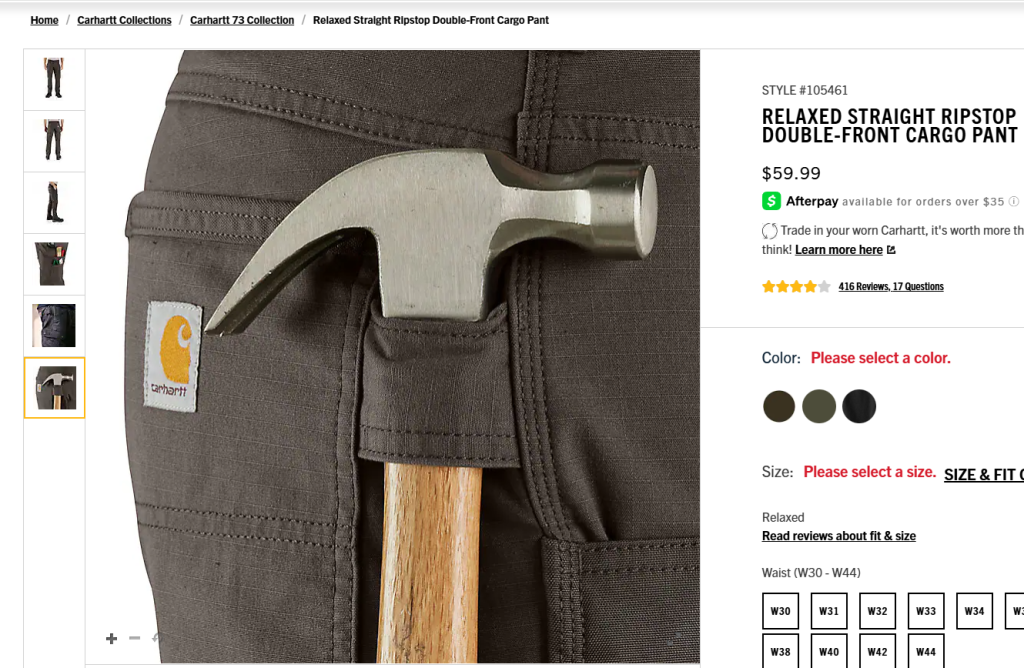

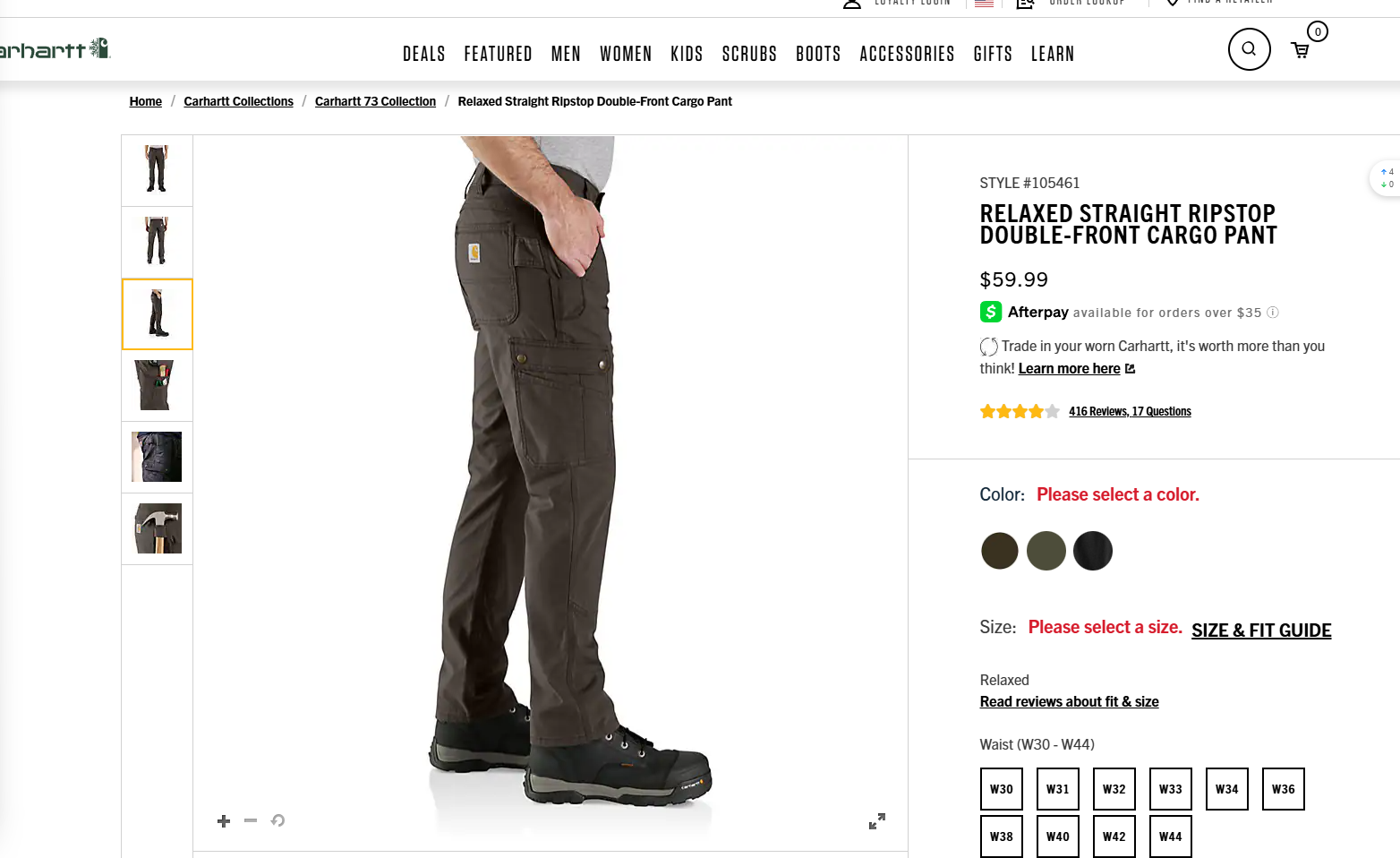

A great example is the Carhartt Relaxed Fit Ripstop Double Front Cargo Pant, made from a 58% cotton / 39% polyester / 3% spandex stretch ripstop. This composition offers durability for real work, while also delivering the stretch and recovery urban consumers expect in daily wear.

Carhartt Ripstop Cargo Pants – Cotton-Poly-Spandex Stretch Ripstop

This points to a broader trend: ripstop fabrics are evolving with lifestyle shifts, and blends with spandex or T400 are at the forefront. If you’re looking for a performance fabric that blends stretch with structure, consider this 220gsm T400 spandex ripstop fabric.

Urban brands use ripstop to signal:

- Tactical styling (cargo pockets, paneling, contrast stitching)

- Movement-ready comfort with mechanical stretch

- A bridge between performance and everyday fashion

Traditional Workwear: Function First, Always

In industrial and blue-collar settings, ripstop’s durability and affordability are paramount. Brands like Dickies, Red Kap, and Walls often use cotton-polyester blended ripstop in garments meant for warehouse, factory, or fieldwork environments.

A classic example would be a 65% polyester / 35% cotton ripstop, offering a balance of strength, breathability, and comfort at scale. This 240gsm waterproof poly-cotton ripstop is ideal for uniforms, overalls, and other coatings.

240gsm Poly-Cotton Ripstop – Ideal for Uniforms

In this sector, the focus is not on aesthetic or branding, but on:

- Resistance to tears and punctures

- Long-term durability under stress

- Easy maintenance (machine-washable, stain-resistant)

- Cost-effective mass production

One Fabric, Three Markets: Tailoring the Narrative

Ripstop’s versatility allows it to serve different narratives across markets:

| Segment | Core Focus | Ripstop Usage |

|---|---|---|

| Outdoor Gear | Survival, performance | Weatherproof, lightweight nylon ripstop |

| Urban Fashion | Style, utility aesthetic | Cotton/stretch ripstop for design texture |

| Industrial Workwear | Durability, compliance | Blended ripstop for cost and strength |

For brands, this means the same base fabric can be spun into different value stories, depending on your audience and product positioning.

A good example of crossover material is this 220gsm T400 spandex ripstop, which could be tailored into either:

- Flexible hiking pants for outdoor markets

- Functional joggers for urban streetwear

- Stretch workwear for warehousing uniforms

Fabric Selection Guide: How to Source Ripstop for Your Brand

If you’re sourcing ripstop for your collection, consider:

- Base fiber: Cotton blends (comfort), nylon (durability), polyester (cost)

- Weight (GSM): 150–180gsm for jackets; 200–250gsm for pants and workwear

- Features: Mechanical stretch, waterproof coating, flame retardant, UV protection

- Colorfastness and shrinkage stability

Always request certifications and lab test reports when sourcing industrial or commercial-grade fabrics.

To explore more ripstop options or request swatches, contact us at sales@ripstopfabric.com.