Wet rubbing fastness can be frustrating—especially when you’re working with dark cotton ripstop fabrics. As someone who’s been in this field for years, I’ve seen many buyers puzzled by lab reports that look great on small swatches, only to find the bulk fabric doesn’t perform the same. Let’s break down why that happens—and what you can do about it.

Wet rubbing fastness means how well a fabric resists color transfer when it’s rubbed while wet. For dark cotton-rich ripstop fabrics, the rating often lands around Grade 2 or 3. That’s because deep colors pile up extra dye on the surface, and cotton’s rough texture makes it easier for dye to rub off.

If you’re sourcing workwear fabrics, especially dark ones, it’s worth understanding how this works—before it becomes a quality issue.

What is the meaning of wet fastness?

Simply put, wet fastness is how much color stays on the fabric when it gets wet and rubbed. It’s tested using a crockmeter, where a white cloth is rubbed over the fabric under pressure. If a lot of color transfers, the score drops.

This is different from dry rubbing fastness (which usually tests better) and also different from washing fastness. For workwear, wet rubbing is crucial—especially when sweat or moisture comes into play.

How to improve color fastness to rubbing?

Here are a few ways we help improve wet rubbing fastness in production:

- Fixing agents – These help “lock” the dye onto the fiber.

- Wet rubbing enhancers – Special auxiliaries that improve resistance to transfer.

- Thorough soaping – This washes out the extra floating dye that didn’t bond properly.

- Singeing or mercerizing – These make the fabric surface smoother, so there’s less friction.

- Disperse dye blends – In some cases, choosing disperse dye systems (like 士林 disperse dyes) can help, though they’re not always suitable for cotton.

That said, even with all these steps, deep colors like black, navy, or red usually max out at Grade 2–3 on the scale. That’s just the reality of cotton fiber and color depth.

Why is wet rubbing fastness so poor for dark cotton ripstop fabrics?

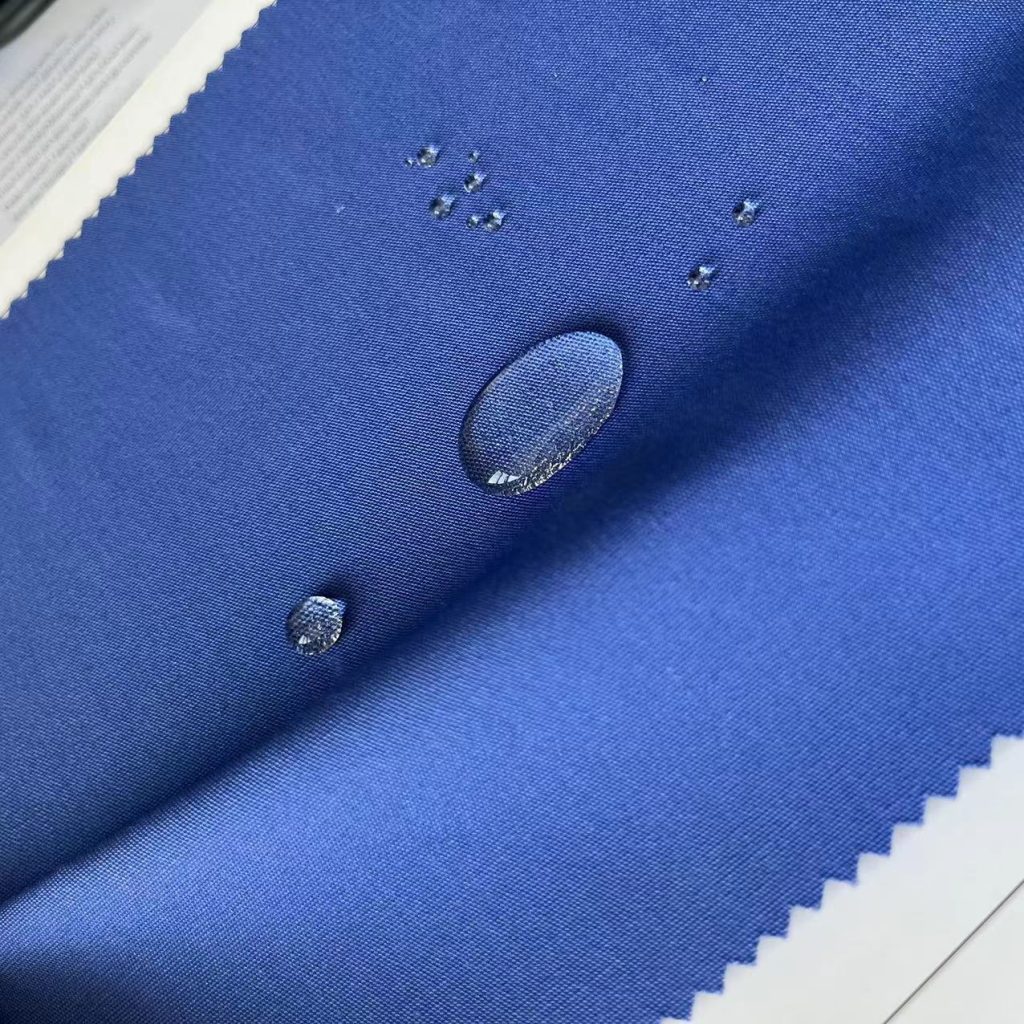

Here’s what’s really happening: dark colors require a lot of dye—often more than the fabric can truly absorb. The excess dye sits on the surface, known as floating color, and that’s what transfers during testing.

Also, ripstop fabric made with cotton has a naturally rougher surface. The more friction, the easier it is to break the bond between the dye and fiber. Combine roughness with wetness, and you get color transfer.

What is ISO 105-X12 and why does it matter for workwear buyers?

ISO 105-X12 is the international test standard for rubbing fastness. It’s the method used in most lab reports. The fabric is rubbed using a white cotton cloth—once dry, once wet—and the stain is rated from 1 (worst) to 5 (best).

For workwear made with dark cotton blends, Grade 3 is generally considered acceptable. Anything above that is rare unless you’re working with synthetics or lighter shades.

📺 Want to see how the test works?

👉 Watch this short demo on YouTube

It’s a great way to see what’s really happening behind those lab scores.

How can buyers communicate realistic wet rubbing fastness expectations to suppliers?

First, don’t rely only on the specification sheet. If you’re aiming for Grade 3 or above, it’s worth confirming whether your sample truly meets that level.

If you can send us a large enough reference swatch, we’ll usually test it in our own lab. Based on that result, we’ll let you know honestly: what grade it’s currently at, whether it can be improved, and realistically, to what extent.

Because we’ve been producing fabrics for decades, we can often make an educated guess about achievable grades based on the fabric and color. But if you’re preparing for a tender or a large program, we strongly recommend running a short trial—say, 50 or 100 meters—and testing that fabric properly. That’s the most reliable way to make sure the bulk fabric performs as expected.

Final thoughts

Dark ripstop fabrics and high wet rubbing fastness don’t always go together—and that’s okay. The key is to set clear expectations and make sure the supplier can meet them in bulk, not just in the lab.

👉 If you’re still deciding between fabric bases, you might also find this article helpful:

Polyester Cotton vs Cotton Ripstop: Which Is Better for Workwear?

Have a project you’re working on? Let’s talk—we’ve seen it all.